Please Choose Your Language

Please Choose Your Language

| Availability: | |

|---|---|

MH-CHP

MINGHUNG

1. Particleboard

Manufacturing Process

Engineered wood panel produced by bonding wood particles with synthetic resin under heat and pressure.

Critical parameters:

Hot Pressing: 180–220℃ (resin-dependent) with multi-stage pressure profiling (max 8 MPa → hold 4 MPa → step decompression)

Density Control: 600–750 kg/m³ achieved by stratified particle size distribution (fine surface / coarse core)

Key features:

Cost-effective materials: Utilizes low-value timber (small logs, branches)

Uniform structure: Free from natural wood defects like knots

Versatile applications: Furniture substrates, partitions, flooring underlayment

Performance Highlights

Dimensional Stability: Moisture content 5–8%, thickness swelling ≤12% (superior to solid wood)

Eco-Certification: E0 grade formaldehyde emission ≤0.5 mg/L (EN 717-1 compliant)

Post-Processing: Compatible with laminating, drilling, and edge-banding

2. Continuous Press Line

Integrated Workflow

Section | Function |

Forming Station | Cross-directional air-suspension forming (3-layer structure, tolerance ±5%) |

Pre-press | Roller compaction (0.5–1.2 MPa) for initial mat consolidation |

Continuous Press | Dual-steel-belt press (30–60 m length) with zone-controlled heating (±2℃) |

Cooling Section | High-pressure water mist (0.8 MPa) for instant surface quenching |

Cross-cut Saw | Servo-driven flying saw (±0.3 mm accuracy), dynamic length adjustment |

Core Innovations

Press Plate Compensation: Hydraulic leveling system (0.05 mm/m flatness)

Belt Tension Control: Laser-guided servo hydraulics (tension variation ≤±1.5%)

Energy Recovery: 60% waste heat reclaimed via boiler (steam consumption: 1.1–1.3 ton/m³)

3. Integrated Features

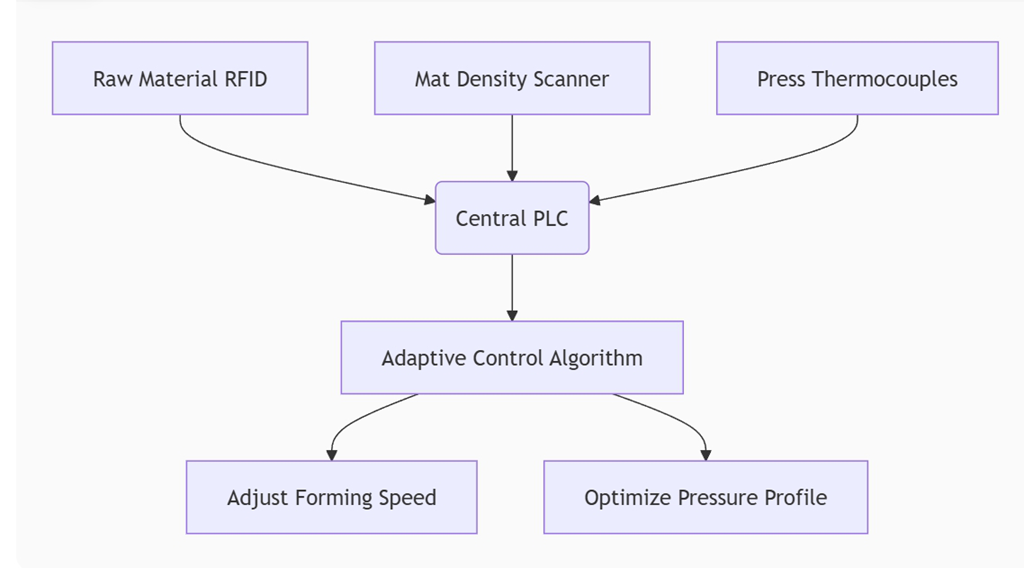

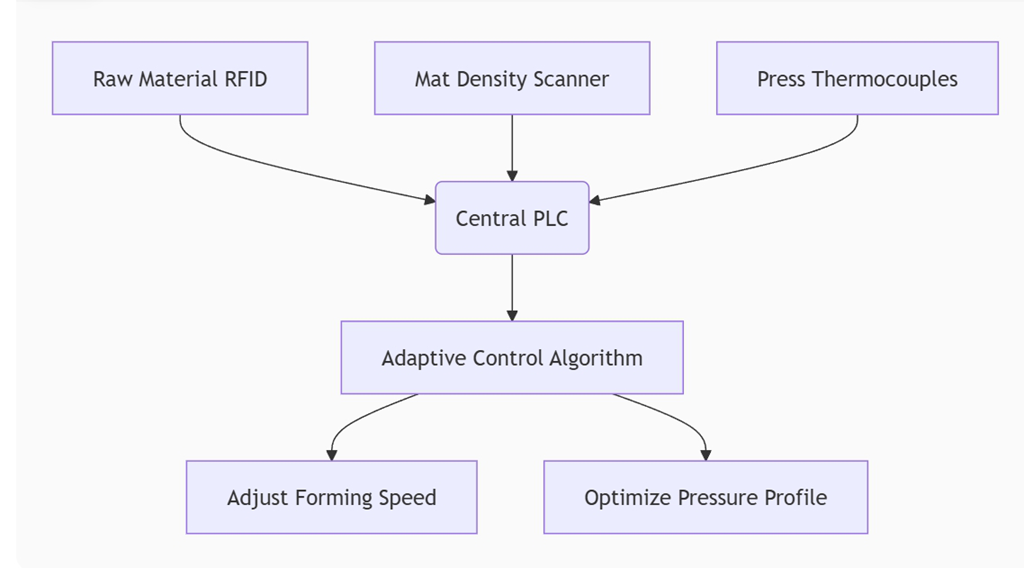

AI-Optimized Control

Smart coordination: PLC system synchronizes forming-pressing-cooling sections (e.g., auto-adjusting pressure based on mat density)

Heat recovery: Waste heat from press reused for particle drying, cutting steam consumption

Modularity: Rapid changeover for varied specifications (thickness: 2.5-40 mm; density: 600-750 kg/m³)

4. Fully Automatic Feeding System

Advanced Modules

Subsystem | Key Technologies |

Pre-processing | Trommel screen (remove >30mm particles) + microwave moisture detection (±0.5%) |

Smart Storage | Dome silo (N₂ inerting) + 3D ultrasonic volume mapping (<1% error) |

Precision Dosing | Twin-screw loss-in-weight feeder (±0.8%) + multi-resin inline blending (±1.2%) |

Safety Systems | Spark detection/extinguishing (response <50ms) + metal separator (Φ≥1.5mm) |

Unmanned raw material handling:

Particle storage: Silo (capacity ≥500 m³) with radar level monitoring

Intelligent conveying:

Variable-frequency screws for precision metering (±1.5%)

Metal detection + spark suppression for safety

Anti-bridging: Silos equipped with vibrators and rotating breakers

Benefits: Eliminates manual handling, prevents contamination, ensures supply continuity

> Overall Efficiency: Material yield ≥97%, energy consumption ≤85 kWh/m³, OEE (Overall Equipment Effectiveness) >88%.

Pre-sales service:

1) Listen to customer needs

2) Provide preliminary machine design and flow chart for free, select and provide the most reasonable configuration equipment:

3) Support remote meetings and remote factory visits;

4) Provide professional advice to customers and confirm the final selection

5) Support on-site factory visits;

On-purchase service:

1) All equipment must be installed and debugged before leaving the factory, and remote video quality inspection is supported;

2) All machines must be unpacked before leaving the factory, and photos, videos, and annotations must be provided;

3) Free online or offline training for buyers' operators (domestic)

4) Assist buyers in installing and debugging equipment (overseas)

After-sales service:

1) 7*24 hours online service, remote real-time video solution;

2) During the first installation and debugging process, problems encountered during normal operation are solved in time:

3) Regular process inspection and use effect, timely machine maintenance suggestions:

4) Lifetime free technical guidance

5) Timely update the latest industry information.

2007-2010

2007 -Our factory started to manufacture the full sets of OSB、PB、MDF Production line.

2013

Shandong Hungyou intelligent Equipment Industry ResearchCo..Ltd established, for plywood machinery and OSB、PB、MDF machinery research and development.The main research direction is to realize the automation of Plywood machinery.

2015

Linyi Ming Hung Trade Co.,Ltd established, the development focus has began to Foreignmarket, to service more foreign customers.

2017

Our High-end brand -ShandongMinghung OSB&MDF Machinery Equipment Manufacturing Co..Ltd established, mainly for foreign customers make the whole plant planning and design,achieve comprehensive high-end automation.

2018

Our High-end brand -Shandong MingHung Wood Machinery Co..Ltd established, mainly for foreign customers make the whole plant planning and design,achieve comprehensive high-end automation.

2022

Our factory's overseas business achieved significant growth,shipped machines to many different countriesl,ike America,Mexico,Columbia,Russia,Indonesia,Vietnam,Malaysia,Thailand,Egypt, TurkishUkraine, Romania, Portugal, Africaand others.

2024

We continue to adhere to the strategy of going global,to become one World brand.

For more information, welcome contact us, we will reply you quickly and offer working videos with you.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com

1. Particleboard

Manufacturing Process

Engineered wood panel produced by bonding wood particles with synthetic resin under heat and pressure.

Critical parameters:

Hot Pressing: 180–220℃ (resin-dependent) with multi-stage pressure profiling (max 8 MPa → hold 4 MPa → step decompression)

Density Control: 600–750 kg/m³ achieved by stratified particle size distribution (fine surface / coarse core)

Key features:

Cost-effective materials: Utilizes low-value timber (small logs, branches)

Uniform structure: Free from natural wood defects like knots

Versatile applications: Furniture substrates, partitions, flooring underlayment

Performance Highlights

Dimensional Stability: Moisture content 5–8%, thickness swelling ≤12% (superior to solid wood)

Eco-Certification: E0 grade formaldehyde emission ≤0.5 mg/L (EN 717-1 compliant)

Post-Processing: Compatible with laminating, drilling, and edge-banding

2. Continuous Press Line

Integrated Workflow

Section | Function |

Forming Station | Cross-directional air-suspension forming (3-layer structure, tolerance ±5%) |

Pre-press | Roller compaction (0.5–1.2 MPa) for initial mat consolidation |

Continuous Press | Dual-steel-belt press (30–60 m length) with zone-controlled heating (±2℃) |

Cooling Section | High-pressure water mist (0.8 MPa) for instant surface quenching |

Cross-cut Saw | Servo-driven flying saw (±0.3 mm accuracy), dynamic length adjustment |

Core Innovations

Press Plate Compensation: Hydraulic leveling system (0.05 mm/m flatness)

Belt Tension Control: Laser-guided servo hydraulics (tension variation ≤±1.5%)

Energy Recovery: 60% waste heat reclaimed via boiler (steam consumption: 1.1–1.3 ton/m³)

3. Integrated Features

AI-Optimized Control

Smart coordination: PLC system synchronizes forming-pressing-cooling sections (e.g., auto-adjusting pressure based on mat density)

Heat recovery: Waste heat from press reused for particle drying, cutting steam consumption

Modularity: Rapid changeover for varied specifications (thickness: 2.5-40 mm; density: 600-750 kg/m³)

4. Fully Automatic Feeding System

Advanced Modules

Subsystem | Key Technologies |

Pre-processing | Trommel screen (remove >30mm particles) + microwave moisture detection (±0.5%) |

Smart Storage | Dome silo (N₂ inerting) + 3D ultrasonic volume mapping (<1% error) |

Precision Dosing | Twin-screw loss-in-weight feeder (±0.8%) + multi-resin inline blending (±1.2%) |

Safety Systems | Spark detection/extinguishing (response <50ms) + metal separator (Φ≥1.5mm) |

Unmanned raw material handling:

Particle storage: Silo (capacity ≥500 m³) with radar level monitoring

Intelligent conveying:

Variable-frequency screws for precision metering (±1.5%)

Metal detection + spark suppression for safety

Anti-bridging: Silos equipped with vibrators and rotating breakers

Benefits: Eliminates manual handling, prevents contamination, ensures supply continuity

> Overall Efficiency: Material yield ≥97%, energy consumption ≤85 kWh/m³, OEE (Overall Equipment Effectiveness) >88%.

Pre-sales service:

1) Listen to customer needs

2) Provide preliminary machine design and flow chart for free, select and provide the most reasonable configuration equipment:

3) Support remote meetings and remote factory visits;

4) Provide professional advice to customers and confirm the final selection

5) Support on-site factory visits;

On-purchase service:

1) All equipment must be installed and debugged before leaving the factory, and remote video quality inspection is supported;

2) All machines must be unpacked before leaving the factory, and photos, videos, and annotations must be provided;

3) Free online or offline training for buyers' operators (domestic)

4) Assist buyers in installing and debugging equipment (overseas)

After-sales service:

1) 7*24 hours online service, remote real-time video solution;

2) During the first installation and debugging process, problems encountered during normal operation are solved in time:

3) Regular process inspection and use effect, timely machine maintenance suggestions:

4) Lifetime free technical guidance

5) Timely update the latest industry information.

2007-2010

2007 -Our factory started to manufacture the full sets of OSB、PB、MDF Production line.

2013

Shandong Hungyou intelligent Equipment Industry ResearchCo..Ltd established, for plywood machinery and OSB、PB、MDF machinery research and development.The main research direction is to realize the automation of Plywood machinery.

2015

Linyi Ming Hung Trade Co.,Ltd established, the development focus has began to Foreignmarket, to service more foreign customers.

2017

Our High-end brand -ShandongMinghung OSB&MDF Machinery Equipment Manufacturing Co..Ltd established, mainly for foreign customers make the whole plant planning and design,achieve comprehensive high-end automation.

2018

Our High-end brand -Shandong MingHung Wood Machinery Co..Ltd established, mainly for foreign customers make the whole plant planning and design,achieve comprehensive high-end automation.

2022

Our factory's overseas business achieved significant growth,shipped machines to many different countriesl,ike America,Mexico,Columbia,Russia,Indonesia,Vietnam,Malaysia,Thailand,Egypt, TurkishUkraine, Romania, Portugal, Africaand others.

2024

We continue to adhere to the strategy of going global,to become one World brand.

For more information, welcome contact us, we will reply you quickly and offer working videos with you.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com