Please Choose Your Language

Please Choose Your Language

| Availability: | |

|---|---|

MH-CHP

MINGHUNG

This high-performance continuous flat press machine is optimized for MDF (Medium-Density Fiberboard) and HDF (High-Density Fiberboard) production. Equipped with Siemens PLC control, it ensures precise adjustment of pressure, temperature, and speed, improving board density uniformity and reducing waste.

Siemens' flagship PLC (simple logic controller) is designed for mid-to-high-end industrial automation scenarios. It has high performance, high automation and automation as its core advantages, and is suitable for complex applications such as intelligent manufacturing, process control, and motion control.

Among them, SIMATIC S7-1500 represents the current technical benchmark in the field of industrial control. Its open architecture and digital genes provide core support for the upgrade of Industry 4.0. For modern factories that pursue efficiency, reliability and intelligence, it is an ideal automation center solution.

Operating Principle: Continuous Flat Press

1. Feeding

Pre-formed continuous fiber mat (pre-pressed) enters the press via in-feed conveyor, typically equipped with metal detection systems to prevent mechanical damage.

2. Nip Closure Zone

- The mat progresses into a tapered wedge section with progressively reduced height.

- Upper/lower steel belts (or heated platens) initiate closure, applying gradual compression (15-25% initial density increase) to expel entrapped air.

3. Main Pressing Zone

- Mat enters parallel sections under precisely controlled pressure (up to 6.9 MPa / 1,000 psi) via hydraulic cylinders.

- Thermal energy transfer: Hot oil/steam circulates through platens (180-230°C), achieving:

→ Lignin plasticization for fiber bonding

→ Rapid curing of binders (UF/PF/MDI) within 90-120 seconds

4. Thickness Calibration Zone

- Laser-guided pressure profiling adjusts local compression to:

✓ Compensate mat density variations (±1.5%)

✓ Maintain thickness tolerance ≤±0.1mm (EN 319 compliance)

- Critical for producing warp-free structural panels

5. Pressure Release Zone

- Controlled decompression over 1.5-2.5m length prevents:

-Allow the internal stress of the sheet material to release slowly

-Reduce the "springback" and deformation of the sheet materials

6. Discharge

Cured continuous board exits for downstream processing:

① Cooling tunnels (forced-air)

② Cross-cut saws (±0.5mm length accuracy)

③ Sanding lines (Ra ≤3.2μm surface finish)

cooling

edge trimming and cutting

sanding

Key Features

✔ High Efficiency: annual output of 15000m³, suitable for various factory scales.

✔ Precision Control: PLC + HMI interface for real-time monitoring.

✔ Energy Saving: Thermal oil heating system reduces power consumption by 15%.

✔ Durable Structure: Reinforced steel belt with 10+ years lifespan.

✔ Low Maintenance: Modular design for easy part replacement.

HMI interface

hydraulic station

steel frame

Technical Specifications

Parameter | Value |

Max Pressure | 10 MPa |

Heating System | Thermal Oil Circulation |

Control System | Siemens PLC + Touchscreen |

Board Thickness | 2-40mm |

Power Supply | 380V/50Hz |

Applications

- Furniture manufacturing (cabinets, flooring substrates)

- Architectural decoration (wall panels, acoustic materials)

- Packaging industry (pallets, logistics packaging)

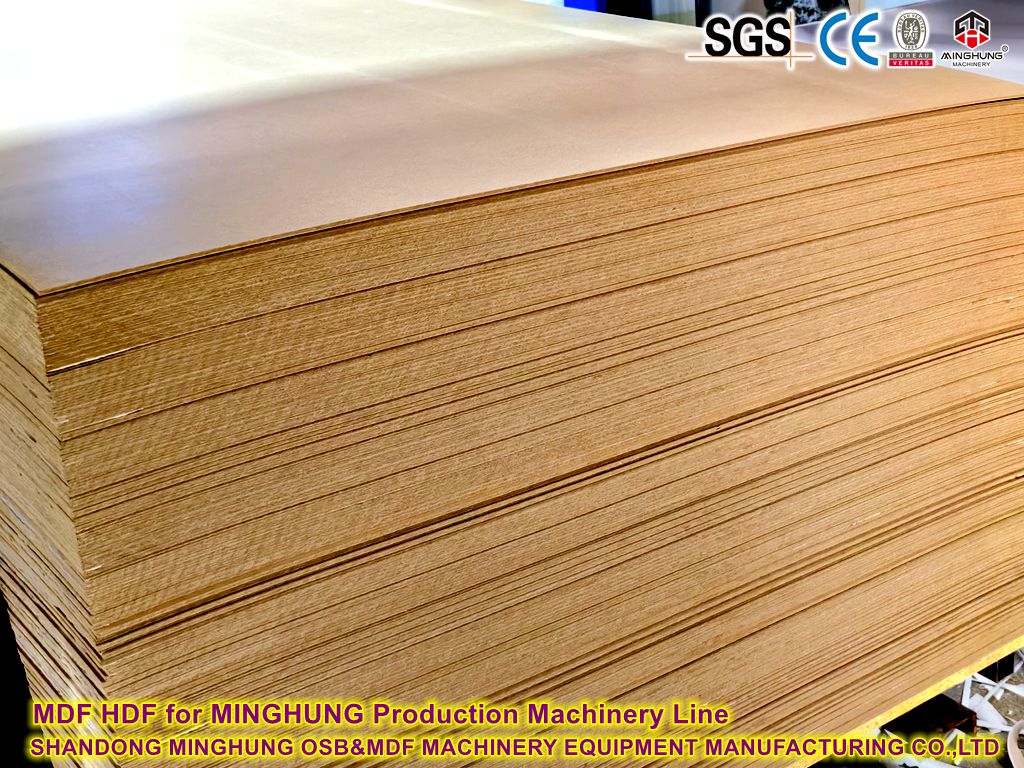

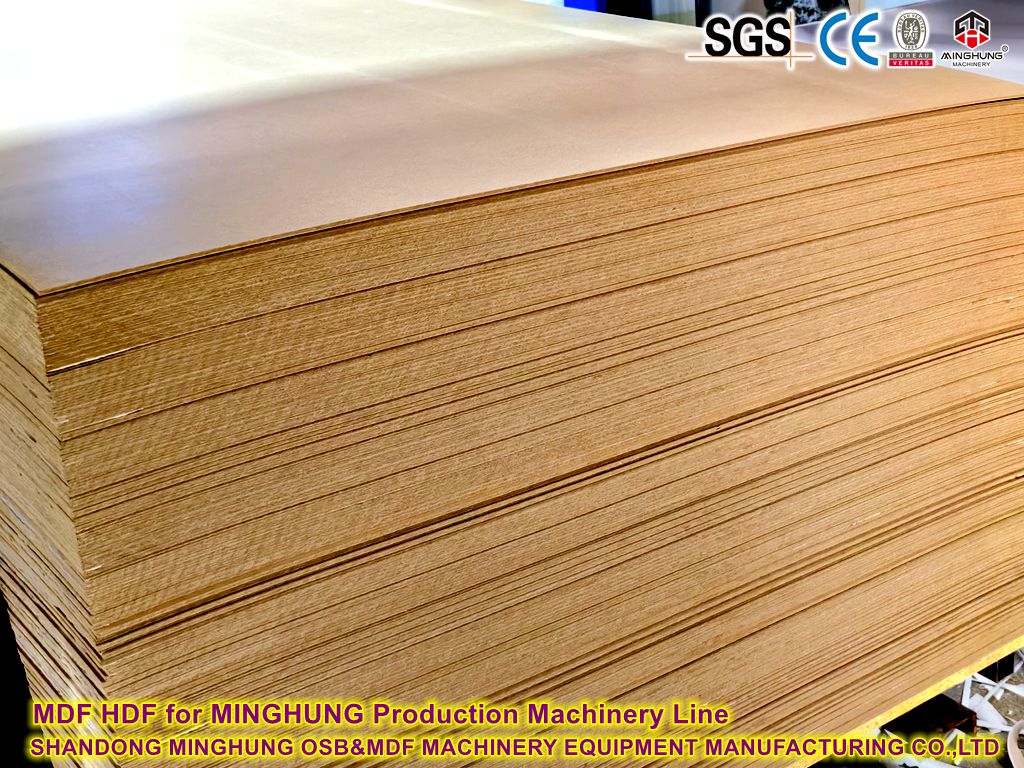

Fiberboard

Fiberboard is an engineered wood product made by refining wood/plant fibers, blending with binders, and hot-pressing. Classified by density:

High-Density Fiberboard (HDF): ≥800 kg/m³ (Thickness: 2.5~6mm)

Medium-Density Fiberboard (MDF): 650~800 kg/m³ (6~40mm)

Low-Density Fiberboard (LDF): <650 kg/m³ (Acoustic/thermal insulation)

MDF vs. Competing Panels

Type | Raw Material | Eco-Level(Formaldehyde) | Strength | Moisture Res. | Cost |

Particleboard | Wood particles | E1~E0 | ★★☆☆☆ | ★★☆☆☆ | ★☆☆☆☆(Low) |

MDF | Wood fiber powder | E1~E0 | ★★★☆☆ | ★★☆☆☆ | ★★☆☆☆ |

Plywood | Cross-laminated veneers | E1~E0 | ★★★★☆ | ★★★☆☆ | ★★★☆☆ |

OSB | Oriented strands | E0 | ★★★★★ | ★★★★☆ | ★★★☆☆ |

After-Sales Service

✓ 24/7 technical support

✓ 1-year warranty + lifetime maintenance

✓ Installation & training provided

Contact us for a free quote today!

Our contacts:

+86 18769900191, +86 15805496117, +86 18954906501

This high-performance continuous flat press machine is optimized for MDF (Medium-Density Fiberboard) and HDF (High-Density Fiberboard) production. Equipped with Siemens PLC control, it ensures precise adjustment of pressure, temperature, and speed, improving board density uniformity and reducing waste.

Siemens' flagship PLC (simple logic controller) is designed for mid-to-high-end industrial automation scenarios. It has high performance, high automation and automation as its core advantages, and is suitable for complex applications such as intelligent manufacturing, process control, and motion control.

Among them, SIMATIC S7-1500 represents the current technical benchmark in the field of industrial control. Its open architecture and digital genes provide core support for the upgrade of Industry 4.0. For modern factories that pursue efficiency, reliability and intelligence, it is an ideal automation center solution.

Operating Principle: Continuous Flat Press

1. Feeding

Pre-formed continuous fiber mat (pre-pressed) enters the press via in-feed conveyor, typically equipped with metal detection systems to prevent mechanical damage.

2. Nip Closure Zone

- The mat progresses into a tapered wedge section with progressively reduced height.

- Upper/lower steel belts (or heated platens) initiate closure, applying gradual compression (15-25% initial density increase) to expel entrapped air.

3. Main Pressing Zone

- Mat enters parallel sections under precisely controlled pressure (up to 6.9 MPa / 1,000 psi) via hydraulic cylinders.

- Thermal energy transfer: Hot oil/steam circulates through platens (180-230°C), achieving:

→ Lignin plasticization for fiber bonding

→ Rapid curing of binders (UF/PF/MDI) within 90-120 seconds

4. Thickness Calibration Zone

- Laser-guided pressure profiling adjusts local compression to:

✓ Compensate mat density variations (±1.5%)

✓ Maintain thickness tolerance ≤±0.1mm (EN 319 compliance)

- Critical for producing warp-free structural panels

5. Pressure Release Zone

- Controlled decompression over 1.5-2.5m length prevents:

-Allow the internal stress of the sheet material to release slowly

-Reduce the "springback" and deformation of the sheet materials

6. Discharge

Cured continuous board exits for downstream processing:

① Cooling tunnels (forced-air)

② Cross-cut saws (±0.5mm length accuracy)

③ Sanding lines (Ra ≤3.2μm surface finish)

cooling

edge trimming and cutting

sanding

Key Features

✔ High Efficiency: annual output of 15000m³, suitable for various factory scales.

✔ Precision Control: PLC + HMI interface for real-time monitoring.

✔ Energy Saving: Thermal oil heating system reduces power consumption by 15%.

✔ Durable Structure: Reinforced steel belt with 10+ years lifespan.

✔ Low Maintenance: Modular design for easy part replacement.

HMI interface

hydraulic station

steel frame

Technical Specifications

Parameter | Value |

Max Pressure | 10 MPa |

Heating System | Thermal Oil Circulation |

Control System | Siemens PLC + Touchscreen |

Board Thickness | 2-40mm |

Power Supply | 380V/50Hz |

Applications

- Furniture manufacturing (cabinets, flooring substrates)

- Architectural decoration (wall panels, acoustic materials)

- Packaging industry (pallets, logistics packaging)

Fiberboard

Fiberboard is an engineered wood product made by refining wood/plant fibers, blending with binders, and hot-pressing. Classified by density:

High-Density Fiberboard (HDF): ≥800 kg/m³ (Thickness: 2.5~6mm)

Medium-Density Fiberboard (MDF): 650~800 kg/m³ (6~40mm)

Low-Density Fiberboard (LDF): <650 kg/m³ (Acoustic/thermal insulation)

MDF vs. Competing Panels

Type | Raw Material | Eco-Level(Formaldehyde) | Strength | Moisture Res. | Cost |

Particleboard | Wood particles | E1~E0 | ★★☆☆☆ | ★★☆☆☆ | ★☆☆☆☆(Low) |

MDF | Wood fiber powder | E1~E0 | ★★★☆☆ | ★★☆☆☆ | ★★☆☆☆ |

Plywood | Cross-laminated veneers | E1~E0 | ★★★★☆ | ★★★☆☆ | ★★★☆☆ |

OSB | Oriented strands | E0 | ★★★★★ | ★★★★☆ | ★★★☆☆ |

After-Sales Service

✓ 24/7 technical support

✓ 1-year warranty + lifetime maintenance

✓ Installation & training provided

Contact us for a free quote today!

Our contacts:

+86 18769900191, +86 15805496117, +86 18954906501