Please Choose Your Language

Please Choose Your Language

| Availability: | |

|---|---|

MINGHUNG

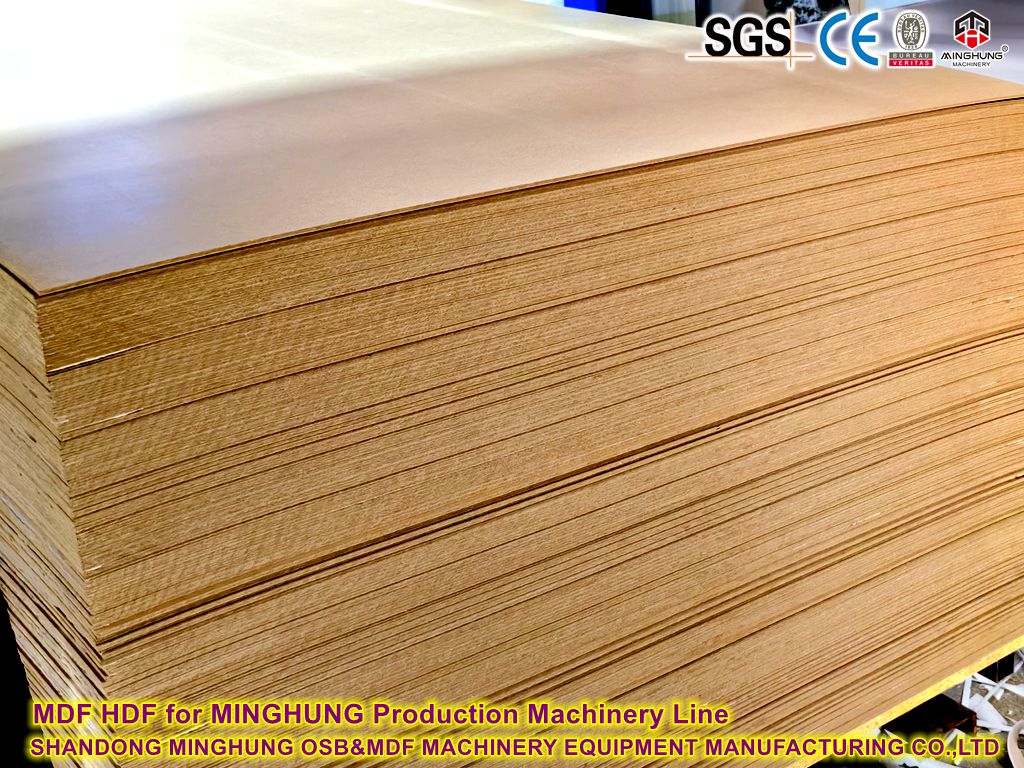

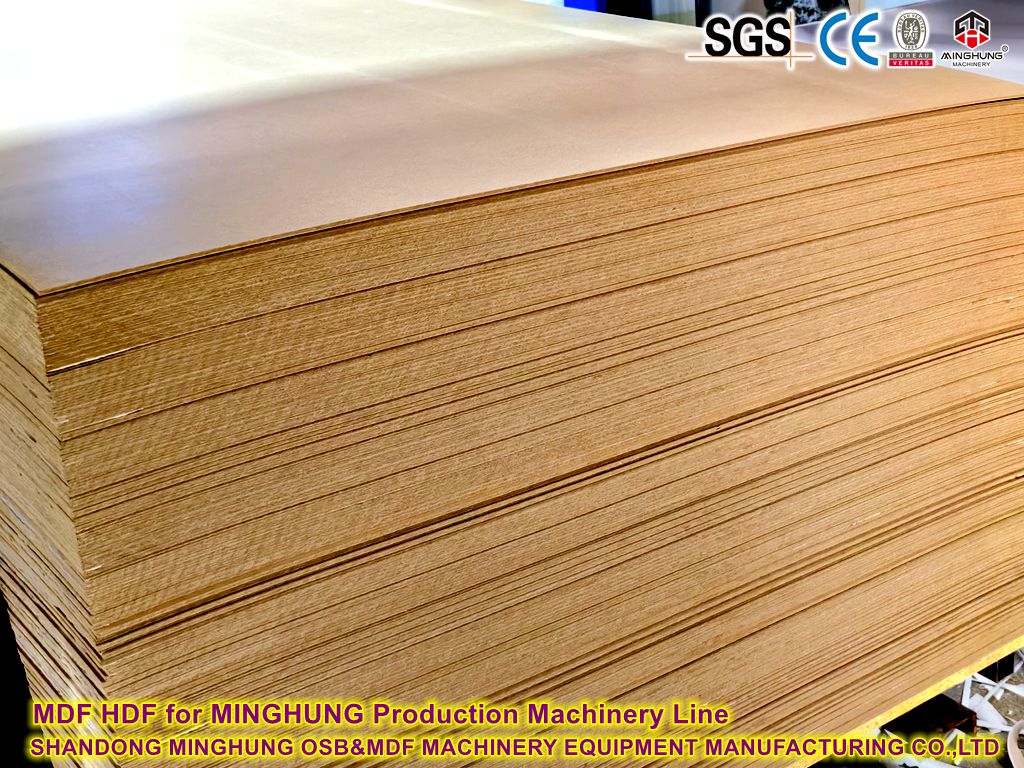

A MDF Continuous Calendering Press Production Line is a state-of-the-art manufacturing system for producing Medium Density Fiberboard (MDF) using a continuous pressing process (calendering), replacing traditional batch presses. It offers higher efficiency, better consistency, and lower operating costs.

Core Components:

1. Raw Material Preparation:

Debarking & Chipping: Logs are debarked and chipped into uniform wood chips.

Chip Washing & Screening: Chips are washed to remove dirt/contaminants and screened for size uniformity.

Chip Storage Silos: Cleaned chips are stored before refining.

2. Fiber Production (Defibration):

Pre-Steaming: Chips are steamed to soften lignin.

Refiner (Defibrator): Steamed chips are broken down into individual fibers under high pressure and temperature (often using pressurized disc refiners).

Resin & Additive Blending:

Resin Application: Liquid resins (typically Urea-Formaldehyde or Melamine-Urea-Formaldehyde) are sprayed onto the hot fibers in a blow-line or blender.

Additive Application: Wax (for water resistance), release agents, hardeners, pigments, etc., are added simultaneously.

Fiber Drying: Resinated fibers are dried in a high-temperature tube dryer to achieve precise moisture content (typically 8-12%).

3. Mat Formation:

Fiber Storage Bins: Dried fibers are temporarily stored.

Mat Forming Station: Fibers are mechanically or pneumatically distributed onto a continuously moving forming conveyor to create a uniform, loose fiber mat (carpet). Weight scanning ensures consistent density. Pre-pressing might occur here.

4. The Continuous Calendering Press (Heart of the Line):

Continuous Belt Press: Unlike traditional multi-opening presses, this press operates continuously. The fiber mat enters between two very long, highly polished, heated steel belts (top and bottom).

Heated Platens/Drums: The belts are pressed together and heated by large, heated cylinders (drums) or heated platens along the press length.

Progressive Compression & Heating: As the mat moves through the press:

It is progressively compressed to the final board thickness.

It is heated uniformly through its thickness via conduction from both belts.

The resin cures (polymerizes) under controlled heat and pressure, bonding the fibers into a solid board.

Key Advantages:

High Speed: Continuous operation allows much faster production rates (e.g., 1000-2000+ m³/day).

Superior Thickness Consistency: Precise control across the entire width and length.

Excellent Surface Quality: Highly polished belts produce very smooth surfaces ready for finishing.

Improved Density Profile: More uniform density through the board thickness.

Energy Efficiency: Lower specific energy consumption per m³ compared to batch presses.

Automation & Control: Highly automated with precise process control (temp, pressure, speed).

5. Post-Pressing Processing:

Cooling Star: The hot, rigid board exits the press and enters a multi-tiered cooling conveyor system to stabilize it and reduce internal stresses.

Sanding: Boards pass through multi-head calibrating sanders to achieve precise final thickness, smoothness, and flatness.

Cutting & Trimming:

Cross Cutting: The continuous board is cut to final panel length (e.g., 2440mm, 2800mm).

Edge Trimming: Rough edges are trimmed off.

Stacking & Inspection: Panels are automatically stacked, inspected (often using automated scanning systems), and labeled.

Storage & Dispatch: Stacks are transferred to storage areas before dispatch.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com

A MDF Continuous Calendering Press Production Line is a state-of-the-art manufacturing system for producing Medium Density Fiberboard (MDF) using a continuous pressing process (calendering), replacing traditional batch presses. It offers higher efficiency, better consistency, and lower operating costs.

Core Components:

1. Raw Material Preparation:

Debarking & Chipping: Logs are debarked and chipped into uniform wood chips.

Chip Washing & Screening: Chips are washed to remove dirt/contaminants and screened for size uniformity.

Chip Storage Silos: Cleaned chips are stored before refining.

2. Fiber Production (Defibration):

Pre-Steaming: Chips are steamed to soften lignin.

Refiner (Defibrator): Steamed chips are broken down into individual fibers under high pressure and temperature (often using pressurized disc refiners).

Resin & Additive Blending:

Resin Application: Liquid resins (typically Urea-Formaldehyde or Melamine-Urea-Formaldehyde) are sprayed onto the hot fibers in a blow-line or blender.

Additive Application: Wax (for water resistance), release agents, hardeners, pigments, etc., are added simultaneously.

Fiber Drying: Resinated fibers are dried in a high-temperature tube dryer to achieve precise moisture content (typically 8-12%).

3. Mat Formation:

Fiber Storage Bins: Dried fibers are temporarily stored.

Mat Forming Station: Fibers are mechanically or pneumatically distributed onto a continuously moving forming conveyor to create a uniform, loose fiber mat (carpet). Weight scanning ensures consistent density. Pre-pressing might occur here.

4. The Continuous Calendering Press (Heart of the Line):

Continuous Belt Press: Unlike traditional multi-opening presses, this press operates continuously. The fiber mat enters between two very long, highly polished, heated steel belts (top and bottom).

Heated Platens/Drums: The belts are pressed together and heated by large, heated cylinders (drums) or heated platens along the press length.

Progressive Compression & Heating: As the mat moves through the press:

It is progressively compressed to the final board thickness.

It is heated uniformly through its thickness via conduction from both belts.

The resin cures (polymerizes) under controlled heat and pressure, bonding the fibers into a solid board.

Key Advantages:

High Speed: Continuous operation allows much faster production rates (e.g., 1000-2000+ m³/day).

Superior Thickness Consistency: Precise control across the entire width and length.

Excellent Surface Quality: Highly polished belts produce very smooth surfaces ready for finishing.

Improved Density Profile: More uniform density through the board thickness.

Energy Efficiency: Lower specific energy consumption per m³ compared to batch presses.

Automation & Control: Highly automated with precise process control (temp, pressure, speed).

5. Post-Pressing Processing:

Cooling Star: The hot, rigid board exits the press and enters a multi-tiered cooling conveyor system to stabilize it and reduce internal stresses.

Sanding: Boards pass through multi-head calibrating sanders to achieve precise final thickness, smoothness, and flatness.

Cutting & Trimming:

Cross Cutting: The continuous board is cut to final panel length (e.g., 2440mm, 2800mm).

Edge Trimming: Rough edges are trimmed off.

Stacking & Inspection: Panels are automatically stacked, inspected (often using automated scanning systems), and labeled.

Storage & Dispatch: Stacks are transferred to storage areas before dispatch.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com