Please Choose Your Language

Please Choose Your Language

| Availability: | |

|---|---|

MH-CHP

MINGHUNG

|

Product Description

Ⅰ.Continuous pressing machine for artificial boards

1. Core Definition

The Continuous Pressing System is the core equipment in artificial board (MDF/Particleboard/OSB) production lines. It conveys the mat continuously via steel belts or heated platens, achieving high-temperature and high-pressure forming during dynamic movement, replacing traditional intermittent multi-opening presses.

2. Core Structure

| Component | Function Description |

| Steel Belt System | Heat-resistant alloy belts (1.5-2.5mm thick), withstand pressure ≥5MPa, surface temp 200-230℃ |

| Heated Platen Modules | Zoned heating (20-30 zones), independent temp control (±1℃), hydraulic zoned pressure (±0.2MPa) |

Hydraulic Station | High-pressure plunger pumps (28-35MPa), response time ≤0.5s |

| Tensioning Device | Automatic hydraulic compensation for belt elongation, maintaining constant tension (<5% fluctuation) |

3. Workflow

3.1 Feeding: Pre-pressed mat enters from forming station

3.2 Pressing Stages:

High-Pressure Zone: Peak pressure (4-5MPa) at entry for rapid compression

Thickness-Control Zone: Gradual pressure reduction (2-3MPa) to target thickness

Curing Zone: Low pressure (0.5-1MPa) for resin polymerization

3.3 Output: Boards exit continuously at 20-100m/min

4. Technical Advantages

Efficiency Boost: 300% higher output vs. multi-opening presses (annual capacity up to 600,000m³)

Energy Saving: Heat recovery reduces consumption by 15-20% (steam usage ≤1.6 tons/m³ board)

Quality Enhancement: Thickness tolerance ±0.1mm, density variation ≤3%

Eco-Friendliness: Enclosed production reduces formaldehyde emissions (workshop air ≤0.05mg/m³)

Ⅱ. Auto-Calibration System for Continuous Board Presses

1. Core Function

Real-time monitoring of board thickness and density distribution during high-speed production (20-100m/min), with closed-loop control to automatically adjust press parameters, ensuring:

Thickness control: ±0.1mm

Density variation: ≤3%

Flatness: ≤0.2mm/m

2. System Components

Module | Technical Solution |

Online Detection | γ-ray thickness gauge (0.01mm precision) or laser scanner (1000 pts/sec) |

Pressure Control | Hydraulic servo valves (≤10ms response) managing 200+ pressure zones |

Temp Compensation | Infrared thermal imaging + zoned platen temp adjustment (±1℃) |

Central Controller | Real-time OS (RTOS) with <5ms latency |

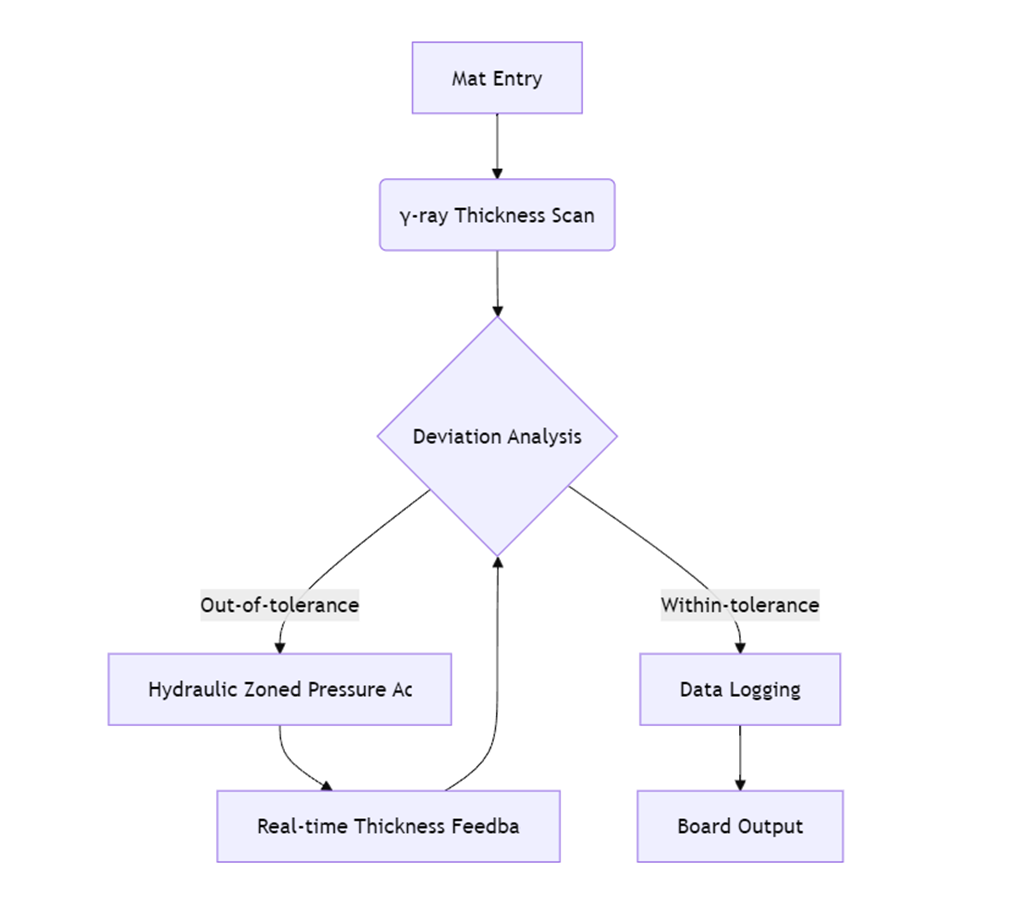

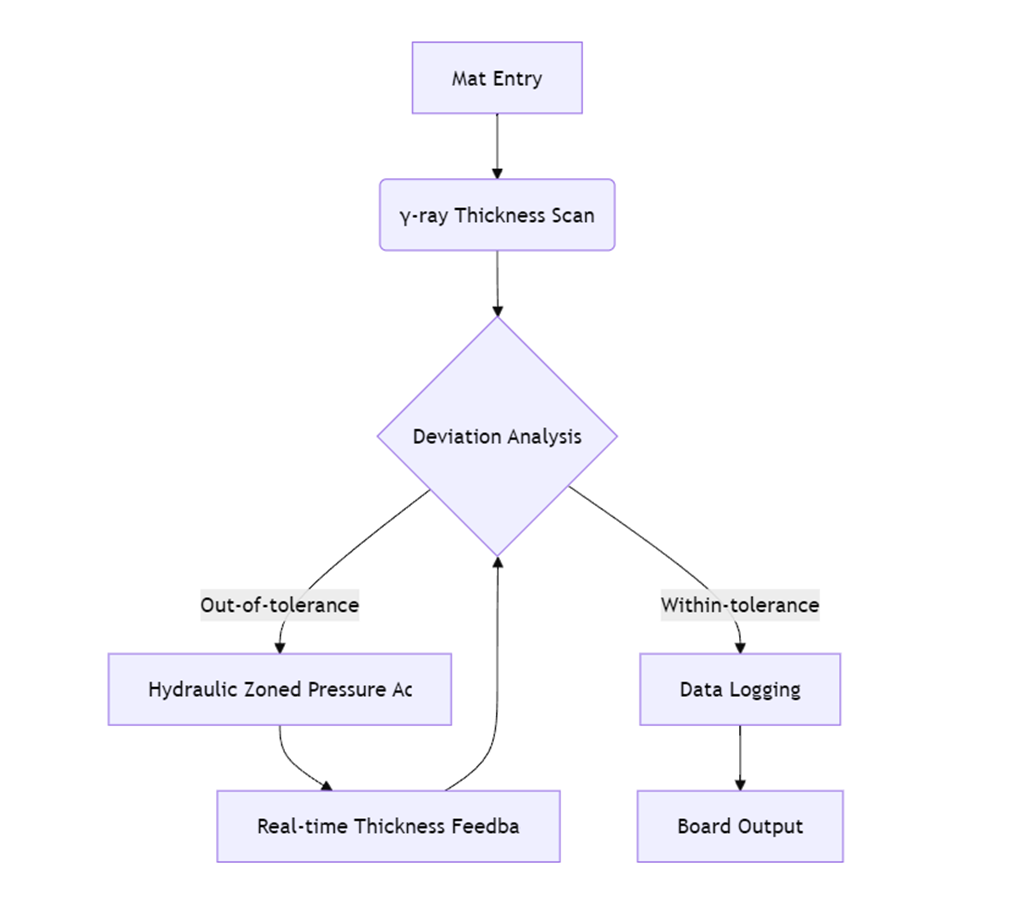

3. Calibration Process

4. Key Technologies

Dynamic Pressure Compensation

Adjusts pressure curve based on moisture (microwave sensor) and thermal expansion prediction

Steel Belt Deformation Correction

Laser profilometers detect belt flatness, hydraulic cylinders auto-compensate (±0.05mm)

Big Data Optimization

AI models trained on historical data optimize pressure-temperature profiles (+3-5% yield)

5. Performance Metrics

Indicator | Pre-Calibration | Post-Calibration | Improvement |

Thickness Yield | 0.895 | 0.992 | 0.097 |

Press Downtime | 7.2/month | 1.5/month | -0.79 |

Raw Material Waste | 4.8t/10k m³ | 2.1t/10k m³ | -0.56 |

Ⅲ.Artificial Boards

Artificial Boards (Engineered Wood Products) are panels manufactured by physically and chemically processing and reconstituting raw materials such as wood or non-wood plant fibers. They overcome the size limitations and defects of natural timber, offering advantages like standardized specifications, controllable performance, and high resource utilization efficiency.

Main Types and Characteristics

1. Plywood

Structure: Composed of an odd number of veneers (thin wood sheets) glued and pressed with their grain directions perpendicular to adjacent layers.

Characteristics:

High bending strength, good dimensional stability

Water resistance grades (WBP/Weather-resistant, MR/Moisture-resistant)

Applications: Concrete formwork, furniture back panels, ship decks.

2. Fiberboard

Raw Material: Wood fibers (from wood processing residues).

Classification:

Type | Density (kg/m³) | Characteristics | Applications |

Hardboard | >900 | Smooth surface, high strength | Furniture doors, laminate flooring |

MDF (Medium Density Fiberboard) | 650-800 | Easy to machine, suitable for carving | Custom furniture, cabinets |

Softboard | <450 | Sound/thermal insulation, low strength | Acoustic panels, packaging liners |

3. Particleboard

Structure: Formed by hot-pressing wood chips or particles bonded with adhesive.

Grades:

Standard Particleboard: Furniture substrates, packing cases

-OSB (Oriented Strand Board): Long wood strands oriented during layup, high mechanical strength, used for structural wall sheathing.

Advantages: Low raw material cost, high eco-friendliness (can use recycled wood).

4. New Eco-friendly Boards

Formaldehyde-Free Boards: Use MDI adhesive (isocyanate) instead of urea-formaldehyde resin, formaldehyde emission ≤0.03mg/m³ (far superior to E0 grade).

Bamboo Scrimber: Reconstituted and glued bamboo strips, strength 2x that of hardwood, used in high-end furniture.

Core Production Processes

1. Raw Material Preparation

Wood → Chipping → Screening → Fiber separation (fiberboard) / Particle preparation (particleboard)

2. Adhesive Application & Additives

Adhesives: Urea-formaldehyde (UF), Phenol-formaldehyde (PF), MDI resin

Additives: Flame retardants (e.g., Al(OH)₃), anti-mold agents

3. Forming & Hot-Pressing

Mat Forming: Air/mechanical forming, determines density uniformity

Hot-Pressing: Temperature 120-220°C, Pressure 2-5MPa, Time adjusted by thickness (~0.4 min/mm)

4. Post-Processing

Sanding (precision ±0.1mm) → Trimming → Surface finishing (melamine paper, wood veneer)

Performance Comparison

Parameter | Solid Wood | Plywood | MDF | OSB |

Bending Strength | Medium | High | Medium | Very High |

Moisture Resistance | Prone to warping | Good (WBP grade) | Requires treatment | Excellent |

Machinability | Grain-dependent | Edge splitting | Carving/curving | Edge chipping |

Eco-friendliness | Formaldehyde-free | E1/E0 grade | Mostly E1 | Low formaldehyde (PF resin) |

Application Fields

Building Structures: OSB for wall sheathing, glulam beams/columns

Furniture Manufacturing: MDF for carved cabinet doors, particleboard for wardrobe bodies

Transportation: Container flooring (bamboo plywood), high-speed train interiors (flame-retardant MDF)

Innovative Applications:

Acoustic Panels: Perforated MDF + sound-absorbing cotton, for concert halls

Anti-static Flooring: Carbon fiber-reinforced MDF, for data centers

|

Product Packaging

OSB making machine

glue blender

continuous pre press

|

Application Video

OSB MDF PB Continuous Hot Press Machine Line

|

Comment & FAQ

Q:Are you a factory or a trading company?

A:We are an industry and trade integrated company with 40 years of experience.

Q:How to choose the right machine?

A:We will check and confirm the type of furniture you manufacture, the process used and the size of the board to recommend the most suitable machine to you.

Q:Can you do OEM /ODM?

A:Yes, we can do OEM/ODM according to your technical requirements

Q:What payment methods do you offer?

A:Usually T/T and LC. If you have other payment methods, we can also consider it.

Q:Why choose you?

A:1.100% customer-oriented solutions.

2.Team members with 40+ years of experience in the wood industry.

3.The strongest awareness of protecting customer business privacy.

4.Deep insight and understanding of market mysteries.

5.Familiar with international terminology.

6.Attention to details and integrity make us grow.

|

Company Profile

We are China professional factory and supplier of OSB board making machine, MDF/HDF making machine and Flakeboard/Particleboard making machine. Whatever which size, thickness, capacity you want to make, and whatever what kinds of raw materials do you use, our professional team can offer a suitable and good solution for you.

From A to Z, from Raw materials to the final wood based panel, we can offer you all necessary machinery. including: Wood chipper, Strander, Disc chipper, Ring flaker, Rotary drum dryer, Vibrating screener, Glue dosing and applying system, Refiner, Mat frorming line, Continuous pre-press, synchronous Cross-cut saw, Multi-layers Hot press /Continuous single layer hot press, Auto edge trimming machine line. Sanding line

In different conditions such as raw materials different, panel thickness and capacity different, glue types different, the whole production line can be different.

|

CertificationClick here to edit your content.

Click here to edit your content.

Click here to edit your content.

Click here to edit your content.

Customize Your Line! Full-service solution from layout design to production optimization. Request a tailored proposal now.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com

|

Product Description

Ⅰ.Continuous pressing machine for artificial boards

1. Core Definition

The Continuous Pressing System is the core equipment in artificial board (MDF/Particleboard/OSB) production lines. It conveys the mat continuously via steel belts or heated platens, achieving high-temperature and high-pressure forming during dynamic movement, replacing traditional intermittent multi-opening presses.

2. Core Structure

| Component | Function Description |

| Steel Belt System | Heat-resistant alloy belts (1.5-2.5mm thick), withstand pressure ≥5MPa, surface temp 200-230℃ |

| Heated Platen Modules | Zoned heating (20-30 zones), independent temp control (±1℃), hydraulic zoned pressure (±0.2MPa) |

Hydraulic Station | High-pressure plunger pumps (28-35MPa), response time ≤0.5s |

| Tensioning Device | Automatic hydraulic compensation for belt elongation, maintaining constant tension (<5% fluctuation) |

3. Workflow

3.1 Feeding: Pre-pressed mat enters from forming station

3.2 Pressing Stages:

High-Pressure Zone: Peak pressure (4-5MPa) at entry for rapid compression

Thickness-Control Zone: Gradual pressure reduction (2-3MPa) to target thickness

Curing Zone: Low pressure (0.5-1MPa) for resin polymerization

3.3 Output: Boards exit continuously at 20-100m/min

4. Technical Advantages

Efficiency Boost: 300% higher output vs. multi-opening presses (annual capacity up to 600,000m³)

Energy Saving: Heat recovery reduces consumption by 15-20% (steam usage ≤1.6 tons/m³ board)

Quality Enhancement: Thickness tolerance ±0.1mm, density variation ≤3%

Eco-Friendliness: Enclosed production reduces formaldehyde emissions (workshop air ≤0.05mg/m³)

Ⅱ. Auto-Calibration System for Continuous Board Presses

1. Core Function

Real-time monitoring of board thickness and density distribution during high-speed production (20-100m/min), with closed-loop control to automatically adjust press parameters, ensuring:

Thickness control: ±0.1mm

Density variation: ≤3%

Flatness: ≤0.2mm/m

2. System Components

Module | Technical Solution |

Online Detection | γ-ray thickness gauge (0.01mm precision) or laser scanner (1000 pts/sec) |

Pressure Control | Hydraulic servo valves (≤10ms response) managing 200+ pressure zones |

Temp Compensation | Infrared thermal imaging + zoned platen temp adjustment (±1℃) |

Central Controller | Real-time OS (RTOS) with <5ms latency |

3. Calibration Process

4. Key Technologies

Dynamic Pressure Compensation

Adjusts pressure curve based on moisture (microwave sensor) and thermal expansion prediction

Steel Belt Deformation Correction

Laser profilometers detect belt flatness, hydraulic cylinders auto-compensate (±0.05mm)

Big Data Optimization

AI models trained on historical data optimize pressure-temperature profiles (+3-5% yield)

5. Performance Metrics

Indicator | Pre-Calibration | Post-Calibration | Improvement |

Thickness Yield | 0.895 | 0.992 | 0.097 |

Press Downtime | 7.2/month | 1.5/month | -0.79 |

Raw Material Waste | 4.8t/10k m³ | 2.1t/10k m³ | -0.56 |

Ⅲ.Artificial Boards

Artificial Boards (Engineered Wood Products) are panels manufactured by physically and chemically processing and reconstituting raw materials such as wood or non-wood plant fibers. They overcome the size limitations and defects of natural timber, offering advantages like standardized specifications, controllable performance, and high resource utilization efficiency.

Main Types and Characteristics

1. Plywood

Structure: Composed of an odd number of veneers (thin wood sheets) glued and pressed with their grain directions perpendicular to adjacent layers.

Characteristics:

High bending strength, good dimensional stability

Water resistance grades (WBP/Weather-resistant, MR/Moisture-resistant)

Applications: Concrete formwork, furniture back panels, ship decks.

2. Fiberboard

Raw Material: Wood fibers (from wood processing residues).

Classification:

Type | Density (kg/m³) | Characteristics | Applications |

Hardboard | >900 | Smooth surface, high strength | Furniture doors, laminate flooring |

MDF (Medium Density Fiberboard) | 650-800 | Easy to machine, suitable for carving | Custom furniture, cabinets |

Softboard | <450 | Sound/thermal insulation, low strength | Acoustic panels, packaging liners |

3. Particleboard

Structure: Formed by hot-pressing wood chips or particles bonded with adhesive.

Grades:

Standard Particleboard: Furniture substrates, packing cases

-OSB (Oriented Strand Board): Long wood strands oriented during layup, high mechanical strength, used for structural wall sheathing.

Advantages: Low raw material cost, high eco-friendliness (can use recycled wood).

4. New Eco-friendly Boards

Formaldehyde-Free Boards: Use MDI adhesive (isocyanate) instead of urea-formaldehyde resin, formaldehyde emission ≤0.03mg/m³ (far superior to E0 grade).

Bamboo Scrimber: Reconstituted and glued bamboo strips, strength 2x that of hardwood, used in high-end furniture.

Core Production Processes

1. Raw Material Preparation

Wood → Chipping → Screening → Fiber separation (fiberboard) / Particle preparation (particleboard)

2. Adhesive Application & Additives

Adhesives: Urea-formaldehyde (UF), Phenol-formaldehyde (PF), MDI resin

Additives: Flame retardants (e.g., Al(OH)₃), anti-mold agents

3. Forming & Hot-Pressing

Mat Forming: Air/mechanical forming, determines density uniformity

Hot-Pressing: Temperature 120-220°C, Pressure 2-5MPa, Time adjusted by thickness (~0.4 min/mm)

4. Post-Processing

Sanding (precision ±0.1mm) → Trimming → Surface finishing (melamine paper, wood veneer)

Performance Comparison

Parameter | Solid Wood | Plywood | MDF | OSB |

Bending Strength | Medium | High | Medium | Very High |

Moisture Resistance | Prone to warping | Good (WBP grade) | Requires treatment | Excellent |

Machinability | Grain-dependent | Edge splitting | Carving/curving | Edge chipping |

Eco-friendliness | Formaldehyde-free | E1/E0 grade | Mostly E1 | Low formaldehyde (PF resin) |

Application Fields

Building Structures: OSB for wall sheathing, glulam beams/columns

Furniture Manufacturing: MDF for carved cabinet doors, particleboard for wardrobe bodies

Transportation: Container flooring (bamboo plywood), high-speed train interiors (flame-retardant MDF)

Innovative Applications:

Acoustic Panels: Perforated MDF + sound-absorbing cotton, for concert halls

Anti-static Flooring: Carbon fiber-reinforced MDF, for data centers

|

Product Packaging

OSB making machine

glue blender

continuous pre press

|

Application Video

OSB MDF PB Continuous Hot Press Machine Line

|

Comment & FAQ

Q:Are you a factory or a trading company?

A:We are an industry and trade integrated company with 40 years of experience.

Q:How to choose the right machine?

A:We will check and confirm the type of furniture you manufacture, the process used and the size of the board to recommend the most suitable machine to you.

Q:Can you do OEM /ODM?

A:Yes, we can do OEM/ODM according to your technical requirements

Q:What payment methods do you offer?

A:Usually T/T and LC. If you have other payment methods, we can also consider it.

Q:Why choose you?

A:1.100% customer-oriented solutions.

2.Team members with 40+ years of experience in the wood industry.

3.The strongest awareness of protecting customer business privacy.

4.Deep insight and understanding of market mysteries.

5.Familiar with international terminology.

6.Attention to details and integrity make us grow.

|

Company Profile

We are China professional factory and supplier of OSB board making machine, MDF/HDF making machine and Flakeboard/Particleboard making machine. Whatever which size, thickness, capacity you want to make, and whatever what kinds of raw materials do you use, our professional team can offer a suitable and good solution for you.

From A to Z, from Raw materials to the final wood based panel, we can offer you all necessary machinery. including: Wood chipper, Strander, Disc chipper, Ring flaker, Rotary drum dryer, Vibrating screener, Glue dosing and applying system, Refiner, Mat frorming line, Continuous pre-press, synchronous Cross-cut saw, Multi-layers Hot press /Continuous single layer hot press, Auto edge trimming machine line. Sanding line

In different conditions such as raw materials different, panel thickness and capacity different, glue types different, the whole production line can be different.

|

CertificationClick here to edit your content.

Click here to edit your content.

Click here to edit your content.

Click here to edit your content.

Customize Your Line! Full-service solution from layout design to production optimization. Request a tailored proposal now.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com