China Professional Plywood Making Machine Manufacturer

Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd

Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd is one famous and professional manufacturer and supplier of Plywood making machine, OSB making machine, Particle board making machine, and MDF/HDF making machine, located in Linyi city, Shandong province, China.

We can design and offer the Suitable & Strong Woodworking machinery for you.

MINGHUNG Plywood Making Machine Introduction

MINGHUNG Wood Based Panel Machine Show

Key Plywood Making Machine Introduction

MINGHUNG MACHINE insist use Good materials & Spare parts to ensure our plywood machine Good & Strong.

And we have professional technicians to design the machines as your requirements.

Veneer Peeling Machine

Veneer peeling machine for making wood veneer through peeling wood such as Beech, Birch, Eucalyptus, Pine, Poplar and others.

Except the standard 4feet and 8feet veneer lathe, we also can design it to be other length like 1800mm, 2000mm, 2900mm, 3200mm and so on.

Our veneer peeling machine is Strong and Powerful, easy peel kinds of Hardwood, and keep the veneer high accuracy and smooth surface.

Veneer Dryer

Veneer dryer for drying humidity/moisture of the peeled veneers, make its final moisture to be 4-10%, for suitable making plywood.

The popular Dryer is Veneer roller dryer, Veneer wire dryer. Both dryer can be designed to be different Length, Width, Floors as your drying capacity and requires.

Hot Press Machine

Hot press machine for Pressing the glued veneer plywood to be solid and strong with High temperature and pressure.

Hot press can be designed to be

different layers from 5-50, and different pressure such as 400Ton, 500Ton,

600Ton, 800Ton, 1000Ton, 1200Ton

Pneumatic Glue Spreader

Glue spreader machine for coating glue on both sides of veneers, so worker can lay the glued veneer up as required plywood thickness and size.

Pneumatic glue spreader is one upgraded type, Compare the traditional glue machine, It adopts a high-performance pneumatic control system and precise glue application roller sets, to achieve uniform, quantitative and highly efficient glue application on both sides of the board.

MINGHUNG Clients

MINGHUNG MACHINE has established a Good and Long relationship with many customers from Different countries such as

Chile, Brazil, Mexico, Bulgaria, Romania, Turkiye, Egypt, Morocco, Ethiopia, Indonesia, Vietnam, Philippines and so on.

MINGHUNG Machinery Delivery

MINGHUNG OSB /MDF /PB Line

OSB Making Machine

OSB(Oriented Strand Board) is one High-strength structural artificial boards made by processing fast-growing woods (such as Poplar, Pine, Bamboo) into large flakes, then through drying, gluing, directional laying, and high-temperature and high-pressure pressing.

We can Offer the Complete OSB Production Line for you as your own demands and requires.

MDF Making Machine

MDF is an ideal base material for high-end furniture and decoration manufacturing. Through completely separating wood or plant fiber raw materials into fibers, and then through processes such as drying, sizing, shaping, and hot pressing, an artificial board with uniform texture and a smooth surface like paper can be produced.

We can offer the Complete MDF/HDF production line for you as your own demands and requires.

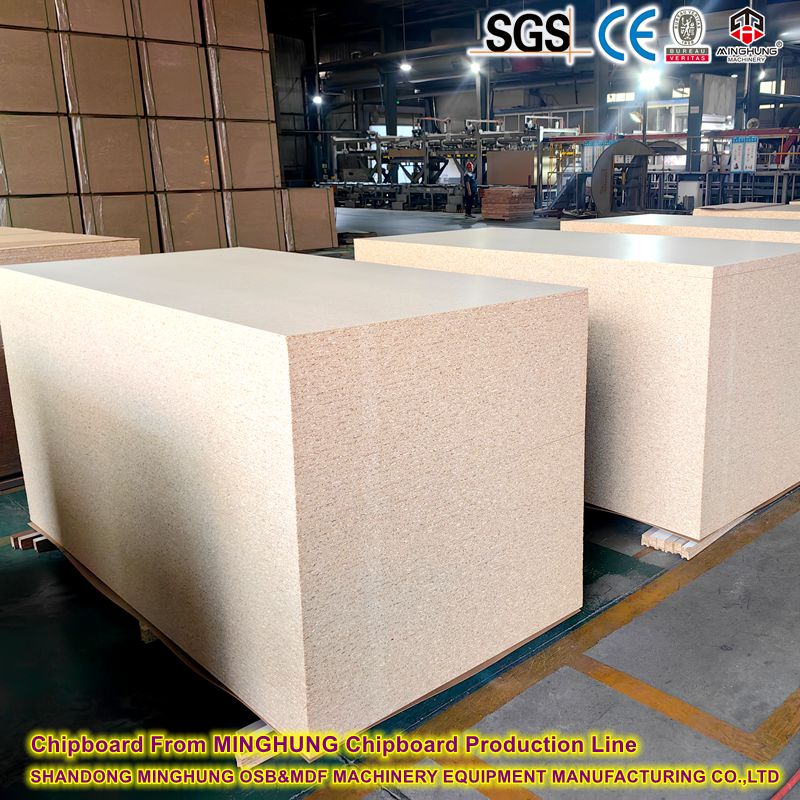

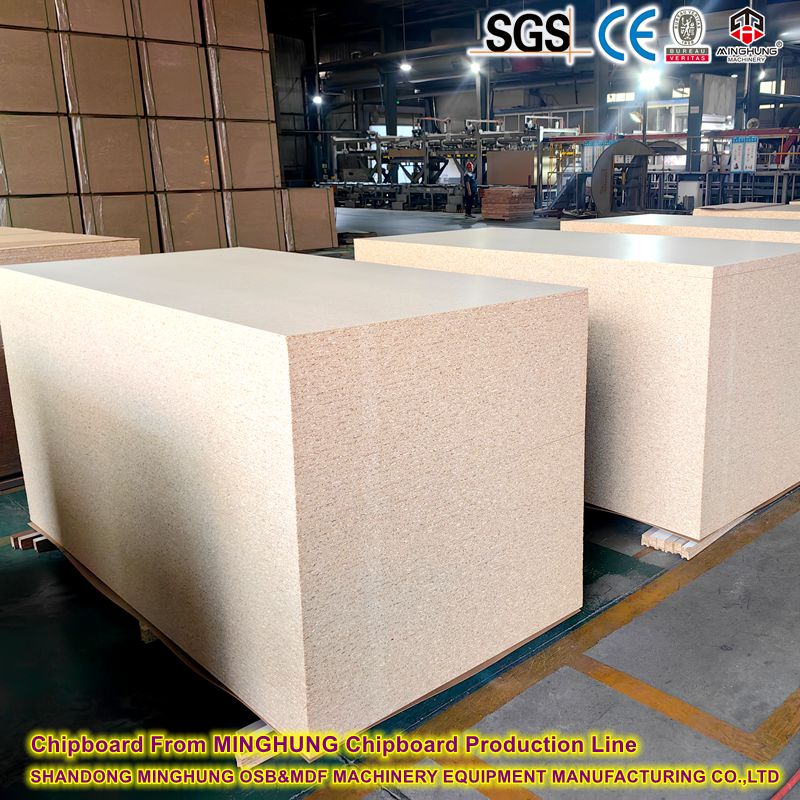

Particle board Making Machine

Particle board /Chipboard is a homogeneous artificial board which made by processing wood waste (such as branch wood, small-diameter logs, sawdust, recycled wood) or agricultural by-product into fine wood shavings, then through drying, gluing, laying and shaping, and hot pressing.

We can offer the Complete Particle board production line for you as your own demands and requires.

Our Certificate

FAQs

Related Blogs

-

In the modern landscape of construction and furniture manufacturing, sustainable and cost-effective materials have taken center stage. Among these, chipboard—often referred to in industrial circles as particle board—has emerged as a cornerstone material. As global demand for recycled wood products g

In the modern landscape of construction and furniture manufacturing, sustainable and cost-effective materials have taken center stage. Among these, chipboard—often referred to in industrial circles as particle board—has emerged as a cornerstone material. As global demand for recycled wood products g

Related Videos

Keep In Touch With Us

Stay connected with us to get the latest updates on Plywood Making Machine technologies, industry trends, and exclusive offers! Whether you want to inquire about customized solutions, consult technical details, or share your production needs, we’re always here to listen and respond promptly. Keep in touch — let’s build a long-term partnership to drive your wood-based panel business forward.

Mob:+86 18769900191 / +86 15589105786 / +86 15805493072

E-mail:osbmdfmachinery@gmail.com