Please Choose Your Language

Please Choose Your Language

| Availability: | |

|---|---|

MH-CHP

MINGHUNG

I. Characteristics of Bamboo Fiberboard (vs. Wood Fiberboard)

Property | Bamboo Fiberboard | Wood Fiberboard |

Raw Material Structure | Hollow long fibers, high silica content (>5%) | Solid short fibers, low silica content |

Density | 0.75-1.2 g/cm³ (higher density potential) | 0.6-0.9 g/cm³ |

Mechanical Strength | Flexural strength ↑30%, Hardness ↑50% | Standard strength |

Water Resistance | Water absorption/swelling ↓15-20% | Higher swelling rate |

Eco-Friendliness | Fast-growing (3-5 years), CO₂ sequestration ↑40% | Long growth cycle (20+ years) |

Processing Challenges | High silica wears equipment, brittle fibers | Better fiber toughness |

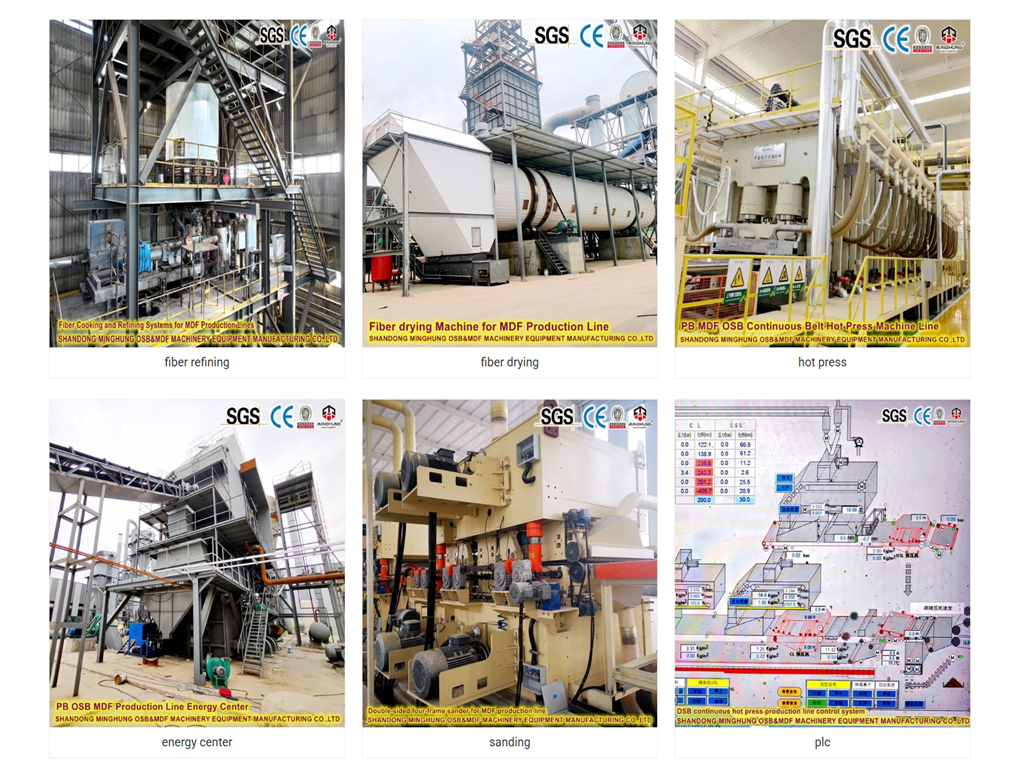

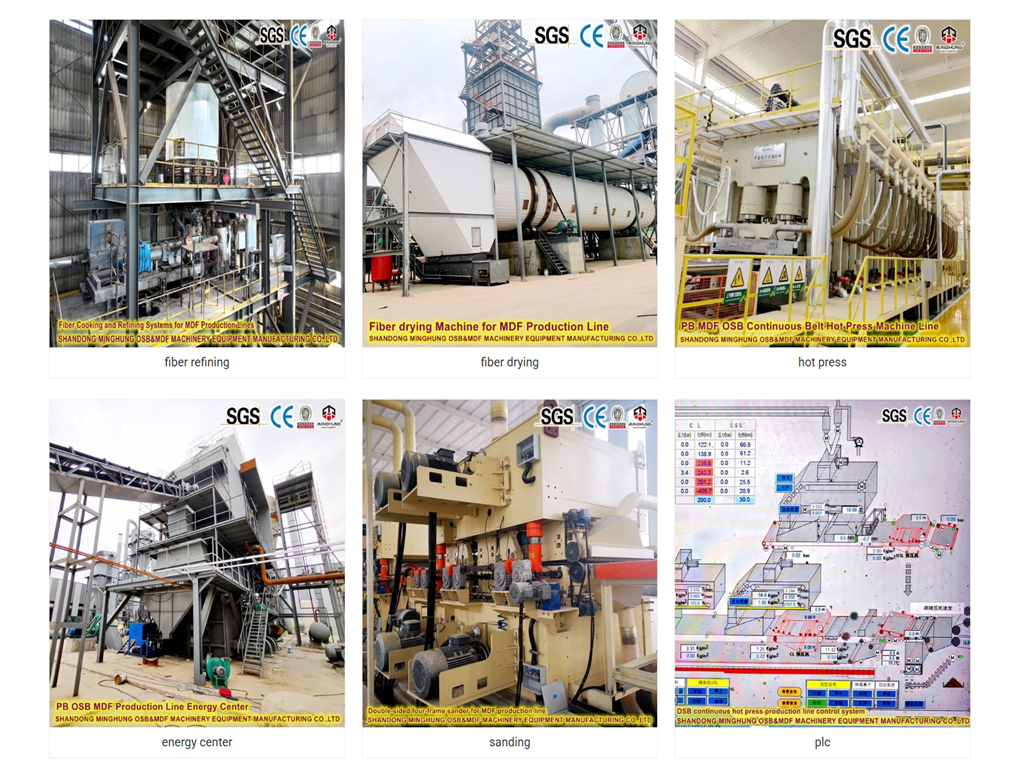

II. Bamboo Fiberboard Production Process

Bamboo Raw Material --> Cutting & Splitting --> Softening Treatment --> Fiber Separation --> Resin Application & Drying --> Mat Forming & Pre-pressing --> Continuous Press Curing -->Cooling & Trimming --> Sanding

1. Raw Material Preparation

Bamboo age: 3-5 year-old moso bamboo (optimal fiber maturity)

Softening process: Saturated steam treatment (0.8-1.2MPa, 160-180°C/30min) to break siliceous layer

2. Fiber Preparation

Refiner temperature: 170-190°C (higher than wood's 150-170°C)

Fiber length: 1.5-2.5mm (preserving long-fiber advantage)

3. Resin Application

Resin types: Modified UF resin / MDI eco-adhesive

Resin content: 8-12% (higher than wood's 6-9%)

4. Mat Forming

Layered structure: Fine surface fibers + Coarse core fibers

Density gradient: Surface density > Core density (0.95/0.75g/cm³)

III. Key Technical Parameters for Bamboo Fiberboard Continuous Press

Parameter | Technical Specifications | Wood Press Comparison |

Working Width | 2600-2800mm (optimized for bamboo) | Typically 2400-2600mm |

Maximum Pressure | 800-1000N/mm² | 500-700N/mm² |

Temperature Control Accuracy | ±1.5°C (multi-zone) | ±2.5°C |

Steel Belt Surface Hardness | HRC58-62 (anti-silica wear) | HRC52-55 |

Press Infeed Height | 120-150mm (high rebound compensation) | 80-100mm |

Curing Speed | 15-25m/min (slower than wood's 30-40m/min) | 30-50m/min |

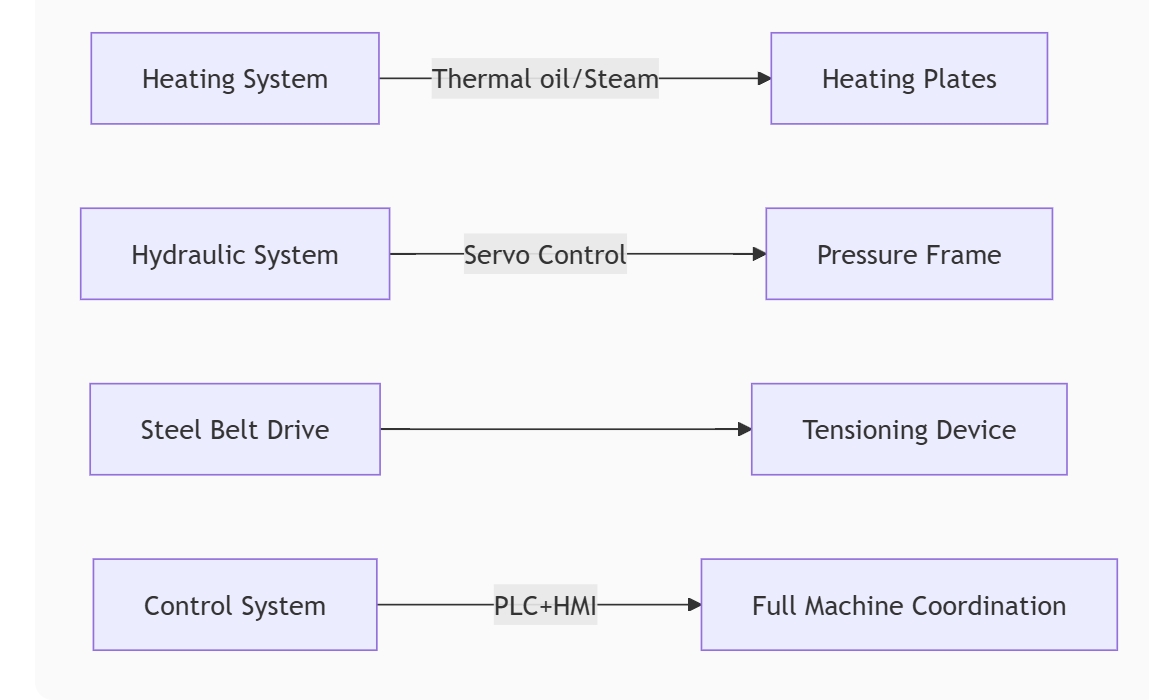

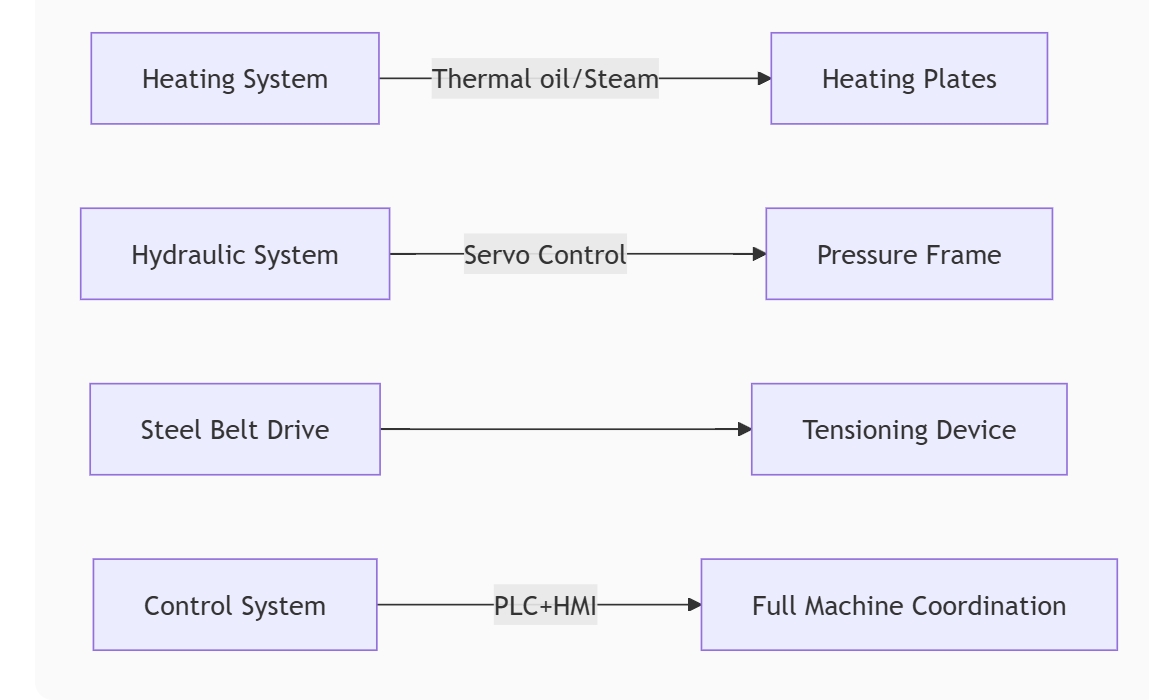

IV. Continuous Press Core Structure & Working Principle

Core System Components

1. Heating System

Zoned design: 8-12 independent temperature zones (ΔT≤3°C)

Heat sources: Thermal oil circulation (max 230°C) or high-pressure steam

2. Pressure Frame

Stepped pressure profile: Infeed > Middle > Outfeed (80%/100%/60%)

Hydraulic compensation: Real-time thickness monitoring (±0.05mm accuracy)

3. Special Wear Resistance

Tungsten carbide-coated steel belt (service life ↑40%)

Ceramic guide roller bearings (anti-silica powder intrusion)

V. Bamboo vs. Wood Fiber Press: Core Differences

Differentiator | Bamboo Fiber Press | Wood Fiber Press |

Pressure System | High-pressure servo hydraulics (response <0.1s) | Standard hydraulic system |

Temperature Profile | Rapid heating phase (180°C→200°C/10s) | Gradual heating |

Infeed Compensation | Elastic pressure rollers (anti-rebound) | Standard pre-press rollers |

Venting Design | High-frequency pulse venting (20x/min) | Conventional venting |

Monitoring System | IR moisture sensor + X-ray density scanner | Basic thickness detection |

Ⅵ. High-Speed Curing: Redefining Bamboo Fiberboard Production Efficiency

As the primary advantage of bamboo fiberboard hot presses, high-speed curing technology breaks traditional efficiency limits through three innovations:

1. Ultra-Conductive Heat Transfer System

Nano-thermal coating (conductivity ≥180 W/m·K) + honeycomb flow channels ensure platen surface ΔT ≤1.5℃

Heat penetration speed reaches 2.3x conventional equipment – 8mm bamboo core hits 180℃ in 18s (vs. 42s traditionally)

2. Resin Reaction Kinetics Optimization

Precision-matched to bamboo fiber characteristics:

High-temp ignition: 170℃→205℃ in 3s to activate MDI resin crosslinking

Pressure infusion: 1000N/mm² forces resin penetration into silica-rich fibers in 0.5s

Curing time reduced to 45-60s (vs. 90-120s for wood boards)

3. Intelligent Pressure-Temperature Synergy

Servo hydraulics adjust pressure every 0.05s (response <80ms)

Gradient temperature strategy:

Infeed zone: 190℃ → Breaks surface silica layer

Mid-zone: 210℃ → Triggers deep curing

Outfeed zone: 175℃ → Completes stress release

Tangible Customer Value

Double Throughput: Line speed up to 25m/min (traditional press ≤12m/min), daily output increases 130%

Energy Savings: Unit energy consumption drops 40% (heat recovery >85%)

Quality Leap: Curing uniformity reaches 98%, internal bond strength achieves 1.05MPa (exceeds EN312 by 42%)

Ⅶ. Core Advantages: Revolutionizing Speed & Efficiency

Ultra-Fast Curing: Optimized heat transfer design and high-response heating/cooling systems drastically reduce the curing time for bamboo fiberboards to industry-leading levels, significantly boosting daily production capacity.

Dedicated to Bamboo: Specifically designed for bamboo fiber characteristics (e.g., density, resilience), it delivers optimal pressure profiles (up to XXX tons) and precise temperature control (XX°C - XX°C), guaranteeing exceptional physical properties, eliminating delamination and warping.

Uniform Consistency: Multi-zone independent temperature control and pressure compensation systems ensure highly uniform heat and pressure distribution across large platen sizes (Max: XXm L x XXm W), eliminating internal stresses and guaranteeing consistent board quality every time.

High-Precision Control: Equipped with an advanced PLC control system and HMI (Human-Machine Interface) for precise setting, real-time monitoring, and logging of critical process parameters (pressure, temperature, time), supporting recipe storage and recall.

Servo Drive (Optional): Utilizes high-performance servo motors to drive the hydraulic system, offering rapid pressure response, high control accuracy, smooth operation, energy savings, and reduced noise.

Robust & Durable: Key components (e.g., heating plates, frame, cylinders) are constructed from high-strength, high-temperature-resistant, and fatigue-resistant materials, ensuring long-term reliability and service life under demanding operating conditions.

Safe & Reliable: Incorporates multiple safety features (safety light curtains, mechanical locks, pressure overload protection, temperature limit alarms, emergency stop buttons) for comprehensive protection of operators and equipment.

High Automation (Optional): Can be integrated with automatic feeding, unloading, and stacking systems for seamless incorporation into automated production lines, reducing labor dependency and boosting overall efficiency.

Energy Efficient & Eco-Friendly: Optimized thermal systems and insulation designs effectively reduce energy consumption. Compatible with eco-friendly heat transfer media (thermal oil/steam).

Applications:

Bamboo Fiberboard (Furniture board, Decorative board, Construction formwork, Flooring substrate, etc.)

Bamboo-Wood Composite Board

Other fiber-reinforced boards requiring rapid high-temperature and high-pressure curing.

Why Choose Our High-Speed Hot Press?

Choosing our dedicated Bamboo Fiberboard High-Speed Hot Press means choosing:

Higher Production Efficiency: Shorter curing times increase output and accelerate ROI.

Superior Product Quality: Uniform pressure and temperature yield more stable, higher-performance bamboo boards.

Lower Unit Cost: Increased efficiency and reduced energy consumption lower the production cost per board.

Enhanced Market Competitiveness: Respond quickly to orders and supply high-quality products consistently.

Worry-Free Production Guarantee: Reliable equipment performance and comprehensive after-sales service ensure smooth, continuous production.

Customization Service:

We offer various specifications and platen layer options. Customized designs based on your specific process requirements (e.g., platen size, pressure needs, automation level) are available to meet your unique production demands.

For more information, welcome contact us, we will reply you quickly and offer working videos with you.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com

I. Characteristics of Bamboo Fiberboard (vs. Wood Fiberboard)

Property | Bamboo Fiberboard | Wood Fiberboard |

Raw Material Structure | Hollow long fibers, high silica content (>5%) | Solid short fibers, low silica content |

Density | 0.75-1.2 g/cm³ (higher density potential) | 0.6-0.9 g/cm³ |

Mechanical Strength | Flexural strength ↑30%, Hardness ↑50% | Standard strength |

Water Resistance | Water absorption/swelling ↓15-20% | Higher swelling rate |

Eco-Friendliness | Fast-growing (3-5 years), CO₂ sequestration ↑40% | Long growth cycle (20+ years) |

Processing Challenges | High silica wears equipment, brittle fibers | Better fiber toughness |

II. Bamboo Fiberboard Production Process

Bamboo Raw Material --> Cutting & Splitting --> Softening Treatment --> Fiber Separation --> Resin Application & Drying --> Mat Forming & Pre-pressing --> Continuous Press Curing -->Cooling & Trimming --> Sanding

1. Raw Material Preparation

Bamboo age: 3-5 year-old moso bamboo (optimal fiber maturity)

Softening process: Saturated steam treatment (0.8-1.2MPa, 160-180°C/30min) to break siliceous layer

2. Fiber Preparation

Refiner temperature: 170-190°C (higher than wood's 150-170°C)

Fiber length: 1.5-2.5mm (preserving long-fiber advantage)

3. Resin Application

Resin types: Modified UF resin / MDI eco-adhesive

Resin content: 8-12% (higher than wood's 6-9%)

4. Mat Forming

Layered structure: Fine surface fibers + Coarse core fibers

Density gradient: Surface density > Core density (0.95/0.75g/cm³)

III. Key Technical Parameters for Bamboo Fiberboard Continuous Press

Parameter | Technical Specifications | Wood Press Comparison |

Working Width | 2600-2800mm (optimized for bamboo) | Typically 2400-2600mm |

Maximum Pressure | 800-1000N/mm² | 500-700N/mm² |

Temperature Control Accuracy | ±1.5°C (multi-zone) | ±2.5°C |

Steel Belt Surface Hardness | HRC58-62 (anti-silica wear) | HRC52-55 |

Press Infeed Height | 120-150mm (high rebound compensation) | 80-100mm |

Curing Speed | 15-25m/min (slower than wood's 30-40m/min) | 30-50m/min |

IV. Continuous Press Core Structure & Working Principle

Core System Components

1. Heating System

Zoned design: 8-12 independent temperature zones (ΔT≤3°C)

Heat sources: Thermal oil circulation (max 230°C) or high-pressure steam

2. Pressure Frame

Stepped pressure profile: Infeed > Middle > Outfeed (80%/100%/60%)

Hydraulic compensation: Real-time thickness monitoring (±0.05mm accuracy)

3. Special Wear Resistance

Tungsten carbide-coated steel belt (service life ↑40%)

Ceramic guide roller bearings (anti-silica powder intrusion)

V. Bamboo vs. Wood Fiber Press: Core Differences

Differentiator | Bamboo Fiber Press | Wood Fiber Press |

Pressure System | High-pressure servo hydraulics (response <0.1s) | Standard hydraulic system |

Temperature Profile | Rapid heating phase (180°C→200°C/10s) | Gradual heating |

Infeed Compensation | Elastic pressure rollers (anti-rebound) | Standard pre-press rollers |

Venting Design | High-frequency pulse venting (20x/min) | Conventional venting |

Monitoring System | IR moisture sensor + X-ray density scanner | Basic thickness detection |

Ⅵ. High-Speed Curing: Redefining Bamboo Fiberboard Production Efficiency

As the primary advantage of bamboo fiberboard hot presses, high-speed curing technology breaks traditional efficiency limits through three innovations:

1. Ultra-Conductive Heat Transfer System

Nano-thermal coating (conductivity ≥180 W/m·K) + honeycomb flow channels ensure platen surface ΔT ≤1.5℃

Heat penetration speed reaches 2.3x conventional equipment – 8mm bamboo core hits 180℃ in 18s (vs. 42s traditionally)

2. Resin Reaction Kinetics Optimization

Precision-matched to bamboo fiber characteristics:

High-temp ignition: 170℃→205℃ in 3s to activate MDI resin crosslinking

Pressure infusion: 1000N/mm² forces resin penetration into silica-rich fibers in 0.5s

Curing time reduced to 45-60s (vs. 90-120s for wood boards)

3. Intelligent Pressure-Temperature Synergy

Servo hydraulics adjust pressure every 0.05s (response <80ms)

Gradient temperature strategy:

Infeed zone: 190℃ → Breaks surface silica layer

Mid-zone: 210℃ → Triggers deep curing

Outfeed zone: 175℃ → Completes stress release

Tangible Customer Value

Double Throughput: Line speed up to 25m/min (traditional press ≤12m/min), daily output increases 130%

Energy Savings: Unit energy consumption drops 40% (heat recovery >85%)

Quality Leap: Curing uniformity reaches 98%, internal bond strength achieves 1.05MPa (exceeds EN312 by 42%)

Ⅶ. Core Advantages: Revolutionizing Speed & Efficiency

Ultra-Fast Curing: Optimized heat transfer design and high-response heating/cooling systems drastically reduce the curing time for bamboo fiberboards to industry-leading levels, significantly boosting daily production capacity.

Dedicated to Bamboo: Specifically designed for bamboo fiber characteristics (e.g., density, resilience), it delivers optimal pressure profiles (up to XXX tons) and precise temperature control (XX°C - XX°C), guaranteeing exceptional physical properties, eliminating delamination and warping.

Uniform Consistency: Multi-zone independent temperature control and pressure compensation systems ensure highly uniform heat and pressure distribution across large platen sizes (Max: XXm L x XXm W), eliminating internal stresses and guaranteeing consistent board quality every time.

High-Precision Control: Equipped with an advanced PLC control system and HMI (Human-Machine Interface) for precise setting, real-time monitoring, and logging of critical process parameters (pressure, temperature, time), supporting recipe storage and recall.

Servo Drive (Optional): Utilizes high-performance servo motors to drive the hydraulic system, offering rapid pressure response, high control accuracy, smooth operation, energy savings, and reduced noise.

Robust & Durable: Key components (e.g., heating plates, frame, cylinders) are constructed from high-strength, high-temperature-resistant, and fatigue-resistant materials, ensuring long-term reliability and service life under demanding operating conditions.

Safe & Reliable: Incorporates multiple safety features (safety light curtains, mechanical locks, pressure overload protection, temperature limit alarms, emergency stop buttons) for comprehensive protection of operators and equipment.

High Automation (Optional): Can be integrated with automatic feeding, unloading, and stacking systems for seamless incorporation into automated production lines, reducing labor dependency and boosting overall efficiency.

Energy Efficient & Eco-Friendly: Optimized thermal systems and insulation designs effectively reduce energy consumption. Compatible with eco-friendly heat transfer media (thermal oil/steam).

Applications:

Bamboo Fiberboard (Furniture board, Decorative board, Construction formwork, Flooring substrate, etc.)

Bamboo-Wood Composite Board

Other fiber-reinforced boards requiring rapid high-temperature and high-pressure curing.

Why Choose Our High-Speed Hot Press?

Choosing our dedicated Bamboo Fiberboard High-Speed Hot Press means choosing:

Higher Production Efficiency: Shorter curing times increase output and accelerate ROI.

Superior Product Quality: Uniform pressure and temperature yield more stable, higher-performance bamboo boards.

Lower Unit Cost: Increased efficiency and reduced energy consumption lower the production cost per board.

Enhanced Market Competitiveness: Respond quickly to orders and supply high-quality products consistently.

Worry-Free Production Guarantee: Reliable equipment performance and comprehensive after-sales service ensure smooth, continuous production.

Customization Service:

We offer various specifications and platen layer options. Customized designs based on your specific process requirements (e.g., platen size, pressure needs, automation level) are available to meet your unique production demands.

For more information, welcome contact us, we will reply you quickly and offer working videos with you.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com