| Availability: | |

|---|---|

MH-MDF-CHP

MINGHUNG

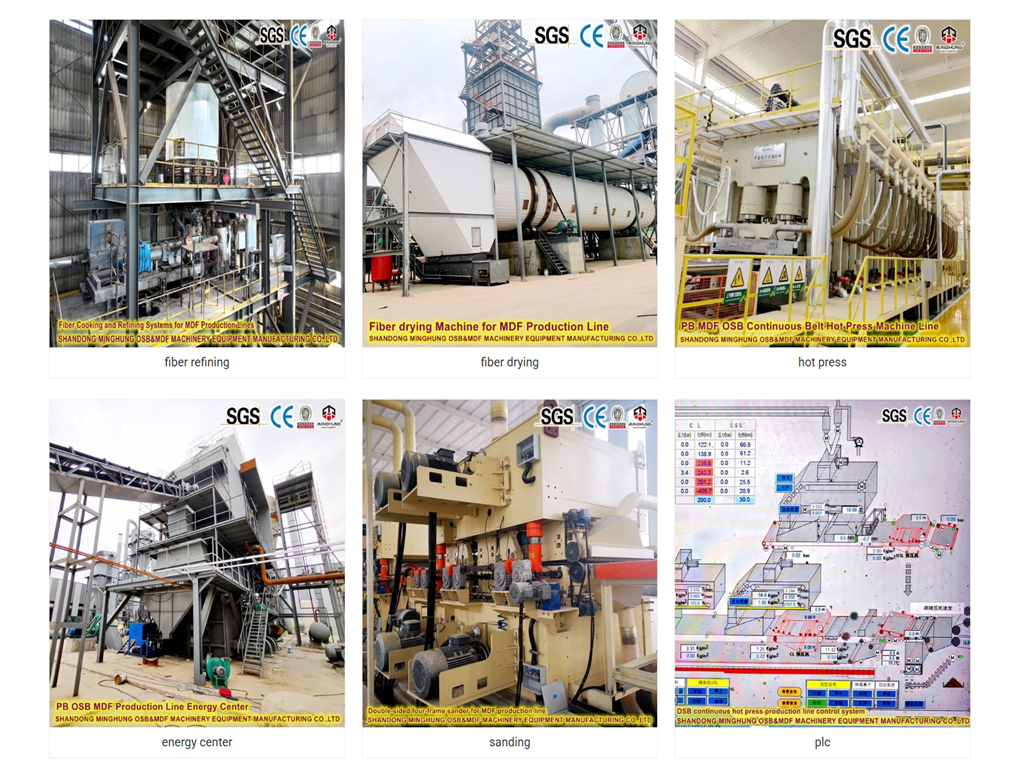

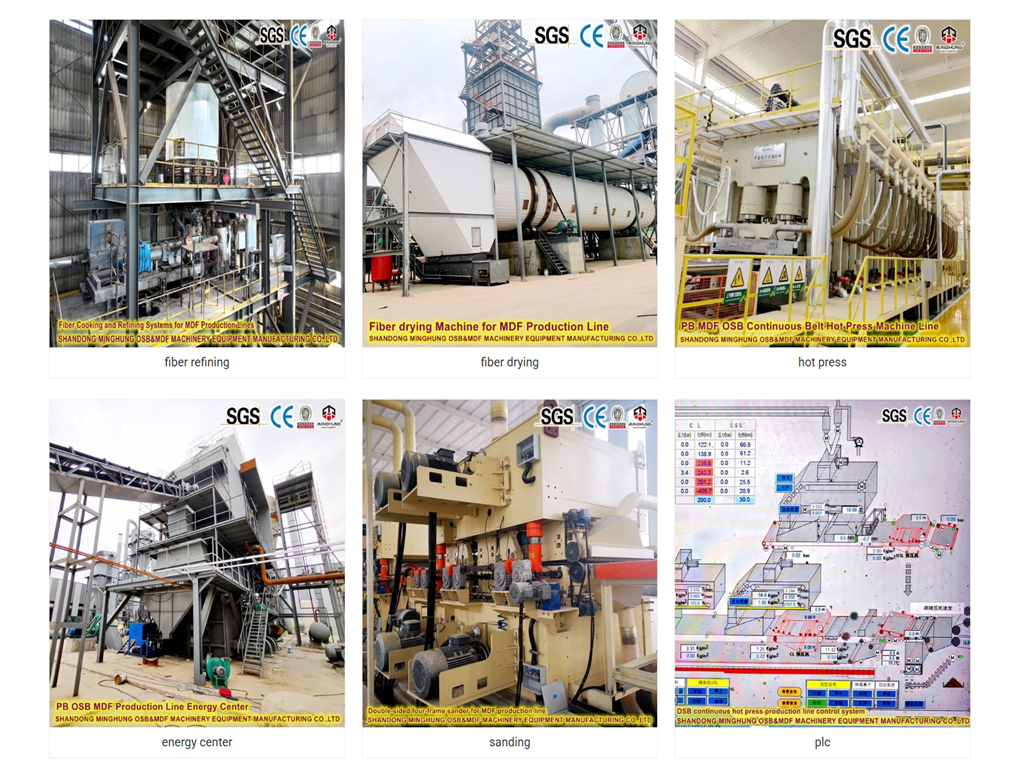

A high-speed MDF continuous press is a continuous flat-press production line specifically designed and optimized for large-scale, high-efficiency manufacturing of Medium Density Fiberboard (MDF), particularly thin panels. It represents not just an acceleration of the press itself, but a comprehensive, synergistic upgrade of the entire production system – from fiber preparation to finishing – to achieve operating speeds and output capacities far exceeding conventional lines.

I. Core Definition

1. Speed Threshold:

Typically refers to a designed maximum line speed ≥ 50 meters per minute (m/min). Top-tier equipment can reach 70-90 m/min or even higher (primarily for thin boards ≤ 6mm thick).

2. Primary Objective:

Maximize production capacity for thin panels (e.g., 3mm, 4mm, 6mm) to meet the large-scale, low-cost demand for thin boards used in furniture, flooring substrates, door skins, etc.

II. Key Technologies & Design Features

1. Extra-Long / Modular Press Section:

Press length is typically ≥ 40 meters (conventional lines ~30-35m), sometimes exceeding 50m.

Extends dwell time in the hot-pressing zone, ensuring sufficient curing for thin boards even at high speeds (thin boards cure quickly, but high speed means more mat passes through per unit time).

Employs modular design for easier maintenance and upgrades.

2. High-Performance Heated Platen System:

Rapid, precise temperature control: Uses efficient heat transfer media (e.g., thermal oil) circulation systems and advanced control algorithms to ensure fast, uniform heating of the mat at high speeds.

High stiffness and flatness: Utilizes special steels and structures to resist deformation under high-speed operation, guaranteeing uniform panel thickness.

3. Advanced Hydraulic/Servo Pressure Control System:

Extremely fast response: Millisecond-level pressure adjustment to meet instantaneous density profile requirements as the mat changes at high speed.

Fine zonal pressure control: More independent pressure zones (e.g., >40 zones) enable more precise density gradient control, ensuring stable board quality at high speeds.

Hydraulic System

Servo Control System

4. High-Speed Forming & Mat Handling System:

Ultra-high precision, high-stability forming station: Capable of uniformly distributing fiber at extreme speeds, preventing density variations or delamination caused by speed.

Rapid pre-pressing and mat feeding: Pre-press and conveyor belts are synchronized for high-speed operation, enabling seamless entry into the press.

MINGHUNG MDF forming machie

pre pressing machine

5. High-Speed Sawing & Finishing Line:

Non-stop high-speed edge trimming/cross-cutting: Employs flying saws or synchronized tracking saws for precise cuts on continuously moving panels, eliminating bottlenecks.

High-speed cooling, stacking, sanding systems: All downstream equipment is matched to high-speed operation to prevent congestion.

cross-cut saw

sanding machine

6. Intelligent Process Control System:

Data & AI-driven: Real-time monitoring of vast process parameters (temp, pressure, speed, density, etc.), using machine learning for prediction and optimization.

Automatic quality inspection & closed-loop control: Integrates online density, moisture, and thickness gauges for real-time feedback and adjustment, ensuring quality stability at speed.

Rapid product changeover (SMED): High automation minimizes downtime when switching product specifications (e.g., thickness), boosting overall efficiency.

7. High-Reliability Design:

Redundancy & reinforcement of critical components: Bearings, drives, hydraulic elements use ultra-durable materials to withstand high-speed, high-load operation.

Predictive maintenance systems: Vibration, temperature sensors, etc., provide early warnings of potential failures, reducing unplanned downtime.

III. Core Advantages of High-Speed Presses

1. Exceptional Thin-Board Capacity: The fundamental purpose. A 2.5m wide high-speed line producing 3mm board at 60 m/min can easily exceed 2,500 cubic meters per day, reaching over 3,000 m³/day.

2. Significantly Reduced Unit Cost: Massive output spreads fixed costs (depreciation, energy, labor, etc.), creating a huge competitive edge, especially in thin board markets.

3. Meets Large-Scale, Stable Supply: Provides stable, high-volume thin board substrates for large furniture and flooring manufacturers.

4. Technology Benchmark & Competitiveness: Represents the industry's most advanced manufacturing level.

Fully Automatic Calibration

I. Core Targets of Fully Automatic Calibration

1. Thickness Uniformity: Ensures thickness deviation across the panel (length/width) is ≤ ±0.1 mm.

2. Density Profile Control: Optimizes core-to-surface density distribution (e.g., "U"-shaped curve), directly impacting strength, screw-holding capacity, and surface quality.

3. Surface Flatness: Prevents waviness, indentations, or gloss inconsistencies.

II. Core Equipment & System Architecture

1. In-line Monitoring Systems (Real-Time Data Acquisition)

Non-Contact Thickness Scanner

- Technology: Laser triangulation, microwave, or beta-ray transmission.

- Location: Installed at press exit or before/after the sander.

- Function: Scans thickness distribution across the panel width in real time (mm resolution), generating thickness maps.

In-line Density Profiler

- Technology: X-ray or gamma-ray transmission scanning.

- Location: Immediately after the thickness scanner (press exit).

- Function: Measures real-time longitudinal/transverse density distribution, plotting density curves.

Surface Inspection System

- Technology: High-resolution line-scan CCD cameras + AI-based image recognition.

- Function: Automatically detects surface defects (pits, scratches, glue spots).

2. Central Control Unit (Data Analysis & Decision-Making)

Industrial Computer:

- Compares real-time data with preset quality models (e.g., target thickness, ideal density curve).

- Uses machine learning models to predict required process adjustments (pressure, temperature, speed).

3. Actuators (Dynamic Parameter Adjustment)

Press Zone Pressure Auto-Adjustment System:

- Equipment: Servo-hydraulic cylinders + high-precision proportional valves (per-zone control).

- Action: Micro-adjusts pressure (±0.5 bar) in individual press zones based on density feedback, optimizing density profile.

Press Platen Temperature Closed-Loop Control:

- Equipment: Thermocouples + smart temperature modules + dynamic thermal oil flow valves.

- Action: Dynamically regulates zonal temperature (±1°C) to ensure uniform curing.

Sander Compensation System (if equipped):

- Equipment: Servo-driven sanding heads + thickness feedback linkage.

- Action: Automatically calculates sanding depth based on thickness data, adjusting belt penetration in real time.

III. Workflow (Closed-Loop Control)

IV. Key Technologies & Innovations

1. Millisecond Response: Full adjustment cycle ≤1 second for dynamic compensation.

2. Big Data-Driven: AI models trained on historical data optimize control strategies (e.g., predicting pressure needs for varying fiber moisture).

3. Cross-System Integration: Synchronizes with upstream forming/blending systems (e.g., auto-adjusting forming parameters based on density feedback).

4. Self-Learning Capability: Continuously refines calibration algorithms using operational data (e.g., adapting to equipment wear).

V. Core Value for Production

1. Quality Enhancement: Thickness tolerance ≤ ±0.1 mm; density profile compliance >99%.

2. Cost Reduction: Lowers sanding allowance (saves raw material); reduces scrap rate by 30–50%.

3. Efficiency Breakthrough: Eliminates manual tuning downtime; cuts product changeover time by 50%.

4. Process Standardization: Removes human expertise dependency; enables "lights-out factory" operation.

Founded in 1983, Shandong MINGHUNG OSB&MDF Machinery Equipment Manufacturing Co.,Ltd., specializes in continuous press solutions for over 40 years.

MINGHUNG is a leading company in the industry of OSB&MDF making machine. With a strongfocus on producing high-quality machinery, we specialize in manufacturing thecomplete production line of Medium density fiberboard (MDF), High densityfiberboard (HDF),Particle board (PB), Oriented strand board (OSB), andVeneerable super strong particle board (LSB).

✅ Transform Your Production Now!

Request Your Customized Quote & Technical Proposal:

Call +86 18769900191, +86 15805496117, +86 18954906501 or 【Live Chat】

Get a productivity upgrade plan within 24h

A high-speed MDF continuous press is a continuous flat-press production line specifically designed and optimized for large-scale, high-efficiency manufacturing of Medium Density Fiberboard (MDF), particularly thin panels. It represents not just an acceleration of the press itself, but a comprehensive, synergistic upgrade of the entire production system – from fiber preparation to finishing – to achieve operating speeds and output capacities far exceeding conventional lines.

I. Core Definition

1. Speed Threshold:

Typically refers to a designed maximum line speed ≥ 50 meters per minute (m/min). Top-tier equipment can reach 70-90 m/min or even higher (primarily for thin boards ≤ 6mm thick).

2. Primary Objective:

Maximize production capacity for thin panels (e.g., 3mm, 4mm, 6mm) to meet the large-scale, low-cost demand for thin boards used in furniture, flooring substrates, door skins, etc.

II. Key Technologies & Design Features

1. Extra-Long / Modular Press Section:

Press length is typically ≥ 40 meters (conventional lines ~30-35m), sometimes exceeding 50m.

Extends dwell time in the hot-pressing zone, ensuring sufficient curing for thin boards even at high speeds (thin boards cure quickly, but high speed means more mat passes through per unit time).

Employs modular design for easier maintenance and upgrades.

2. High-Performance Heated Platen System:

Rapid, precise temperature control: Uses efficient heat transfer media (e.g., thermal oil) circulation systems and advanced control algorithms to ensure fast, uniform heating of the mat at high speeds.

High stiffness and flatness: Utilizes special steels and structures to resist deformation under high-speed operation, guaranteeing uniform panel thickness.

3. Advanced Hydraulic/Servo Pressure Control System:

Extremely fast response: Millisecond-level pressure adjustment to meet instantaneous density profile requirements as the mat changes at high speed.

Fine zonal pressure control: More independent pressure zones (e.g., >40 zones) enable more precise density gradient control, ensuring stable board quality at high speeds.

Hydraulic System

Servo Control System

4. High-Speed Forming & Mat Handling System:

Ultra-high precision, high-stability forming station: Capable of uniformly distributing fiber at extreme speeds, preventing density variations or delamination caused by speed.

Rapid pre-pressing and mat feeding: Pre-press and conveyor belts are synchronized for high-speed operation, enabling seamless entry into the press.

MINGHUNG MDF forming machie

pre pressing machine

5. High-Speed Sawing & Finishing Line:

Non-stop high-speed edge trimming/cross-cutting: Employs flying saws or synchronized tracking saws for precise cuts on continuously moving panels, eliminating bottlenecks.

High-speed cooling, stacking, sanding systems: All downstream equipment is matched to high-speed operation to prevent congestion.

cross-cut saw

sanding machine

6. Intelligent Process Control System:

Data & AI-driven: Real-time monitoring of vast process parameters (temp, pressure, speed, density, etc.), using machine learning for prediction and optimization.

Automatic quality inspection & closed-loop control: Integrates online density, moisture, and thickness gauges for real-time feedback and adjustment, ensuring quality stability at speed.

Rapid product changeover (SMED): High automation minimizes downtime when switching product specifications (e.g., thickness), boosting overall efficiency.

7. High-Reliability Design:

Redundancy & reinforcement of critical components: Bearings, drives, hydraulic elements use ultra-durable materials to withstand high-speed, high-load operation.

Predictive maintenance systems: Vibration, temperature sensors, etc., provide early warnings of potential failures, reducing unplanned downtime.

III. Core Advantages of High-Speed Presses

1. Exceptional Thin-Board Capacity: The fundamental purpose. A 2.5m wide high-speed line producing 3mm board at 60 m/min can easily exceed 2,500 cubic meters per day, reaching over 3,000 m³/day.

2. Significantly Reduced Unit Cost: Massive output spreads fixed costs (depreciation, energy, labor, etc.), creating a huge competitive edge, especially in thin board markets.

3. Meets Large-Scale, Stable Supply: Provides stable, high-volume thin board substrates for large furniture and flooring manufacturers.

4. Technology Benchmark & Competitiveness: Represents the industry's most advanced manufacturing level.

Fully Automatic Calibration

I. Core Targets of Fully Automatic Calibration

1. Thickness Uniformity: Ensures thickness deviation across the panel (length/width) is ≤ ±0.1 mm.

2. Density Profile Control: Optimizes core-to-surface density distribution (e.g., "U"-shaped curve), directly impacting strength, screw-holding capacity, and surface quality.

3. Surface Flatness: Prevents waviness, indentations, or gloss inconsistencies.

II. Core Equipment & System Architecture

1. In-line Monitoring Systems (Real-Time Data Acquisition)

Non-Contact Thickness Scanner

- Technology: Laser triangulation, microwave, or beta-ray transmission.

- Location: Installed at press exit or before/after the sander.

- Function: Scans thickness distribution across the panel width in real time (mm resolution), generating thickness maps.

In-line Density Profiler

- Technology: X-ray or gamma-ray transmission scanning.

- Location: Immediately after the thickness scanner (press exit).

- Function: Measures real-time longitudinal/transverse density distribution, plotting density curves.

Surface Inspection System

- Technology: High-resolution line-scan CCD cameras + AI-based image recognition.

- Function: Automatically detects surface defects (pits, scratches, glue spots).

2. Central Control Unit (Data Analysis & Decision-Making)

Industrial Computer:

- Compares real-time data with preset quality models (e.g., target thickness, ideal density curve).

- Uses machine learning models to predict required process adjustments (pressure, temperature, speed).

3. Actuators (Dynamic Parameter Adjustment)

Press Zone Pressure Auto-Adjustment System:

- Equipment: Servo-hydraulic cylinders + high-precision proportional valves (per-zone control).

- Action: Micro-adjusts pressure (±0.5 bar) in individual press zones based on density feedback, optimizing density profile.

Press Platen Temperature Closed-Loop Control:

- Equipment: Thermocouples + smart temperature modules + dynamic thermal oil flow valves.

- Action: Dynamically regulates zonal temperature (±1°C) to ensure uniform curing.

Sander Compensation System (if equipped):

- Equipment: Servo-driven sanding heads + thickness feedback linkage.

- Action: Automatically calculates sanding depth based on thickness data, adjusting belt penetration in real time.

III. Workflow (Closed-Loop Control)

IV. Key Technologies & Innovations

1. Millisecond Response: Full adjustment cycle ≤1 second for dynamic compensation.

2. Big Data-Driven: AI models trained on historical data optimize control strategies (e.g., predicting pressure needs for varying fiber moisture).

3. Cross-System Integration: Synchronizes with upstream forming/blending systems (e.g., auto-adjusting forming parameters based on density feedback).

4. Self-Learning Capability: Continuously refines calibration algorithms using operational data (e.g., adapting to equipment wear).

V. Core Value for Production

1. Quality Enhancement: Thickness tolerance ≤ ±0.1 mm; density profile compliance >99%.

2. Cost Reduction: Lowers sanding allowance (saves raw material); reduces scrap rate by 30–50%.

3. Efficiency Breakthrough: Eliminates manual tuning downtime; cuts product changeover time by 50%.

4. Process Standardization: Removes human expertise dependency; enables "lights-out factory" operation.

Founded in 1983, Shandong MINGHUNG OSB&MDF Machinery Equipment Manufacturing Co.,Ltd., specializes in continuous press solutions for over 40 years.

MINGHUNG is a leading company in the industry of OSB&MDF making machine. With a strongfocus on producing high-quality machinery, we specialize in manufacturing thecomplete production line of Medium density fiberboard (MDF), High densityfiberboard (HDF),Particle board (PB), Oriented strand board (OSB), andVeneerable super strong particle board (LSB).

✅ Transform Your Production Now!

Request Your Customized Quote & Technical Proposal:

Call +86 18769900191, +86 15805496117, +86 18954906501 or 【Live Chat】

Get a productivity upgrade plan within 24h