Please Choose Your Language

Please Choose Your Language

| Availability: | |

|---|---|

MH-PB

MINGHUNG

I. Overall Overview

A Particleboard Production Line with an Automatic Stacking and Packaging System is a high-end, integrated manufacturing solution in the modern wood-based panel industry. It represents a critical leap from automation to intelligent, unmanned operations in particleboard production. This line not only covers traditional processes from raw material handling to panel pressing but also integrates highly intelligent Automatic Stackers and Automatic Packaging Systems at the end of the line. It achieves full-process automation from "a single panel" to "a packaged product," significantly enhancing production efficiency, product quality, and the overall intelligence of the factory.

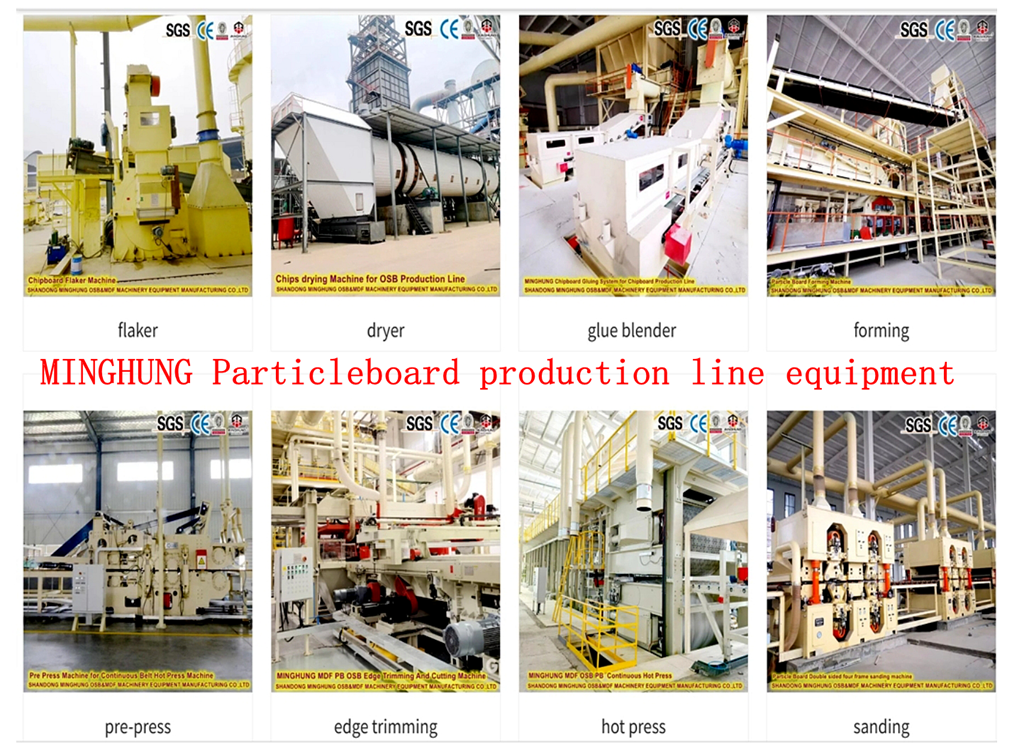

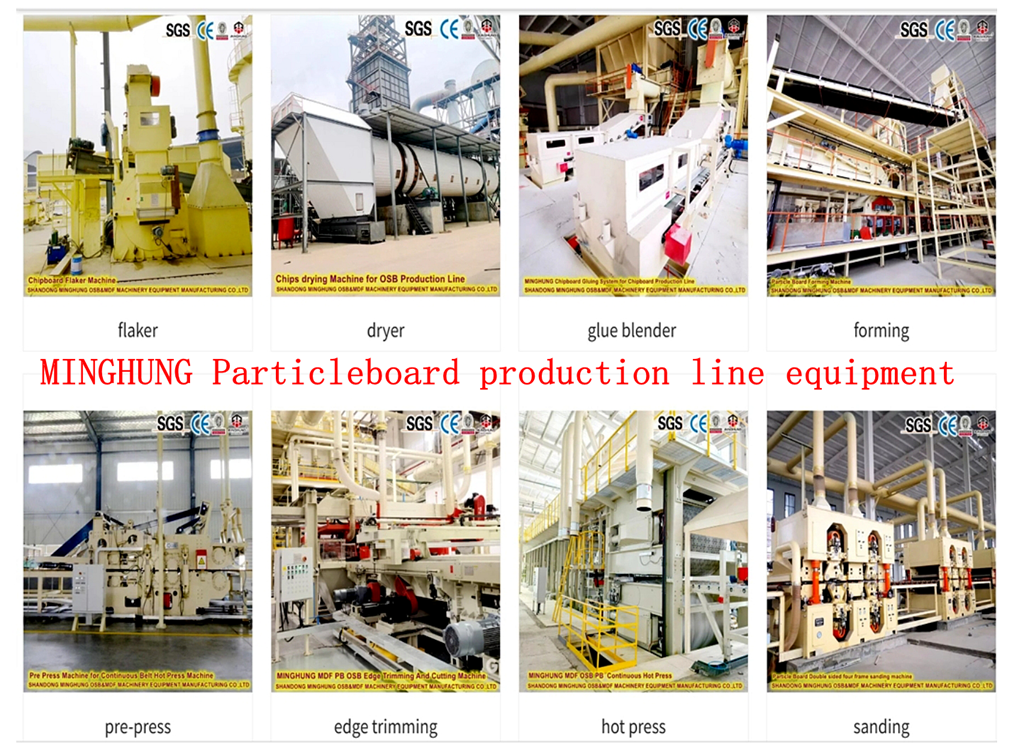

Detailed Workflow Explanation

Stage 1: Front-End Production Process

1. Raw Material Preparation & Blending: Raw materials like wood chips and flakes are screened and dried, then uniformly mixed with resins (glue) and additives in a blender.

2. Forming & Pre-pressing: The resinated particles are formed into a uniform, symmetrical mat via mechanical or air-assisted formers. This mat is then preliminary compacted in a pre-press to form a "green board" with initial strength.

3. Hot Pressing & Curing: The pre-pressed mat enters a multi-opening or continuous press, where it is subjected to high temperature and pressure to cure the resin, ultimately forming a high-strength particleboard.

4. Cooling & Conditioning: The hot-pressed boards are cooled down by a cooling turner and then enter a conditioning area to release internal stresses and stabilize the structure.

5. Sanding & Cutting: The conditioned boards are calibrated to precise thickness and given a smooth surface by a wide-belt sander. Subsequently, they are cut to the final customer dimensions by cross-cut and trim saws.

flaker machine

wood chipper

gluing mixer system

rotary dryer

mat forming machine

pre press

continuous hot press

dryer rack

sanding machine

cross-cut saw

Stage 2: Core Automation - Automatic Stacking & Packaging

This is the value core of the system, beginning after the sanding and cutting.

6. Automatic Sorting & Conveying: Cut-to-size panels are transported via one or multiple conveyor lines. A vision inspection system or sensors perform online detection to identify defective panels (e.g., chipped edges, scratches) and automatically divert them to a reject line. Qualified panels proceed to the stacking station.

7. Intelligent Automatic Stacking:

Stacking Robot/Manipulator: High-precision industrial robots or custom-built stackers use vacuum cups or mechanical grippers to pick single or multiple panels from the conveyor.

Intelligent Stacking Patterns: The system automatically stacks panels according to pre-set schemes (e.g., number of panels per stack, layers, sticker placement). It can automatically recognize panel size and orientation, ensuring every stack is neat, uniform, and structurally stable.

Automatic Sticker Placement: During stacking, the system uses a robotic arm or a dedicated device to automatically place wooden or plastic stickers between the layers of panels. This is crucial for ventilation and preventing surface abrasion, especially for high-quality boards and export shipments.

8. Stack Transfer & Securing: The completed stack is transferred from the stacking station to the packaging station by an automatic forklift or AGV. Before or after transfer, an automatic strapping or stretch-wrapping station may apply initial securing to prevent the stack from collapsing during handling.

9. Fully Automatic Packaging:

Filming/Sheeting: The stack is conveyed into the packaging machine, where a mechanical device automatically drapes a protective plastic film (e.g., PE film) over the stack. This is often done by a "stretch hooding" or "pallet wrapping" machine, where the film is tightly wrapped around the entire stack under tension, forming a waterproof and dustproof layer.

Labeling & Identification: After packaging, an automatic labeler applies labels with product specifications, batch number, production date, barcode, etc., to designated positions on the film.

Corner Protection & Reinforcement: For stacks requiring long-distance transport or higher protection, the system can automatically install paper or wooden edge protectors on the stack's corners and apply additional strapping for reinforcement.

10. Finished Product Output: The packaged stack becomes a standardized product unit ready for direct warehousing or shipping. It is transported to the finished goods warehouse by AGVs or forklifts, awaiting dispatch.

Core Systems & Technical Highlights

Intelligent Control System: Uses PLCs and industrial computers for central control, enabling coordinated operation and data monitoring of the entire line. Operators can easily set production parameters, stacking patterns, and packaging specifications via an HMI.

Machine Vision & Sensing Technology: Used for automatic panel quality inspection, dimension verification, and robot precise positioning, ensuring operational accuracy and consistency.

High-Precision Robotics: The robots used in stacking and packaging feature high speed, high repeatability positioning accuracy, and high reliability, capable of adapting to long-term continuous operation.

Modular & Flexible Design: The production line can be flexibly customized and expanded based on the customer's factory space, capacity requirements (e.g., annual output of 50,000 to 300,000 cubic meters), and product specifications.

Key Advantages & Value Proposition

Ultimate Efficiency Boost: Enables 24/7 continuous production, minimizes manual labor in stacking and packaging, significantly speeds up the production cycle, and markedly increases overall output capacity.

Significant Cost Reduction:

Labor Costs: Reduces reliance on extensive manual labor.

Quality Costs: Automated operations minimize damage like scratches and chipped edges caused by manual handling.

Management Costs: Simplifies production management processes.

Guaranteed Product Quality & Consistency: Mechanical stacking and packaging ensure every stack is uniform in appearance and structure, enhancing brand image and customer satisfaction.

Enhanced Operational Safety: Frees workers from heavy, repetitive, and potentially hazardous tasks, greatly improving the working environment and reducing workplace accidents.

Enables Lean Management & Traceability: The system automatically records production data for each stack and links it to the label information, achieving full life-cycle traceability from raw material to finished product, meeting the requirements of modern smart factories.

What Are the Application Scenarios for Particleboard?

As an economical, eco-friendly, and stable substrate, particleboard has extremely wide applications, covering almost all areas that require panels:

1. Furniture Manufacturing (Core Application)

Panel Furniture: The core substrate for cabinet, wardrobe, TV cabinet, bookcase, office partition, etc. When laminated with melamine-impregnated paper, it becomes the common "Melamine Board" or "Decorative Laminate," ready for furniture production.

Kitchen Furniture: Used for cabinet carcases and doors (especially after laminating or painting).

Office Furniture: Office desks, filing cabinets, conference tables.

2. Construction & Interior Decoration

Floor Underlayment: Serves as a subfloor under hardwood or laminate flooring, providing leveling, stability, and sound insulation.

Partitions & Ceilings: Used for internal non-load-bearing walls and ceiling materials.

Door Core: Acts as the internal filler for solid wood composite doors, reducing weight while ensuring flatness and strength.

3. Customized Home Furnishings & Display Industry

Whole Home Customization: A mainstream material in the whole home customization industry due to its excellent processability and customizability.

Store Displays: Used for shelves, display stands, and feature walls in malls and boutiques, offering cost control and easy surface decoration.

4. Other Industrial Applications

Kitchen & Bathroom Fixtures: Moisture-resistant particleboard is used for vanities in humid environments.

Tabletops & Work Surfaces: Thickened or specially treated particleboard can be used as a substrate for desks, bar counters, etc.

Packaging Cases: Used for making heavy-duty packaging cases or pallets.

Audio Equipment: Some speaker enclosures use high-density particleboard.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com

I. Overall Overview

A Particleboard Production Line with an Automatic Stacking and Packaging System is a high-end, integrated manufacturing solution in the modern wood-based panel industry. It represents a critical leap from automation to intelligent, unmanned operations in particleboard production. This line not only covers traditional processes from raw material handling to panel pressing but also integrates highly intelligent Automatic Stackers and Automatic Packaging Systems at the end of the line. It achieves full-process automation from "a single panel" to "a packaged product," significantly enhancing production efficiency, product quality, and the overall intelligence of the factory.

Detailed Workflow Explanation

Stage 1: Front-End Production Process

1. Raw Material Preparation & Blending: Raw materials like wood chips and flakes are screened and dried, then uniformly mixed with resins (glue) and additives in a blender.

2. Forming & Pre-pressing: The resinated particles are formed into a uniform, symmetrical mat via mechanical or air-assisted formers. This mat is then preliminary compacted in a pre-press to form a "green board" with initial strength.

3. Hot Pressing & Curing: The pre-pressed mat enters a multi-opening or continuous press, where it is subjected to high temperature and pressure to cure the resin, ultimately forming a high-strength particleboard.

4. Cooling & Conditioning: The hot-pressed boards are cooled down by a cooling turner and then enter a conditioning area to release internal stresses and stabilize the structure.

5. Sanding & Cutting: The conditioned boards are calibrated to precise thickness and given a smooth surface by a wide-belt sander. Subsequently, they are cut to the final customer dimensions by cross-cut and trim saws.

flaker machine

wood chipper

gluing mixer system

rotary dryer

mat forming machine

pre press

continuous hot press

dryer rack

sanding machine

cross-cut saw

Stage 2: Core Automation - Automatic Stacking & Packaging

This is the value core of the system, beginning after the sanding and cutting.

6. Automatic Sorting & Conveying: Cut-to-size panels are transported via one or multiple conveyor lines. A vision inspection system or sensors perform online detection to identify defective panels (e.g., chipped edges, scratches) and automatically divert them to a reject line. Qualified panels proceed to the stacking station.

7. Intelligent Automatic Stacking:

Stacking Robot/Manipulator: High-precision industrial robots or custom-built stackers use vacuum cups or mechanical grippers to pick single or multiple panels from the conveyor.

Intelligent Stacking Patterns: The system automatically stacks panels according to pre-set schemes (e.g., number of panels per stack, layers, sticker placement). It can automatically recognize panel size and orientation, ensuring every stack is neat, uniform, and structurally stable.

Automatic Sticker Placement: During stacking, the system uses a robotic arm or a dedicated device to automatically place wooden or plastic stickers between the layers of panels. This is crucial for ventilation and preventing surface abrasion, especially for high-quality boards and export shipments.

8. Stack Transfer & Securing: The completed stack is transferred from the stacking station to the packaging station by an automatic forklift or AGV. Before or after transfer, an automatic strapping or stretch-wrapping station may apply initial securing to prevent the stack from collapsing during handling.

9. Fully Automatic Packaging:

Filming/Sheeting: The stack is conveyed into the packaging machine, where a mechanical device automatically drapes a protective plastic film (e.g., PE film) over the stack. This is often done by a "stretch hooding" or "pallet wrapping" machine, where the film is tightly wrapped around the entire stack under tension, forming a waterproof and dustproof layer.

Labeling & Identification: After packaging, an automatic labeler applies labels with product specifications, batch number, production date, barcode, etc., to designated positions on the film.

Corner Protection & Reinforcement: For stacks requiring long-distance transport or higher protection, the system can automatically install paper or wooden edge protectors on the stack's corners and apply additional strapping for reinforcement.

10. Finished Product Output: The packaged stack becomes a standardized product unit ready for direct warehousing or shipping. It is transported to the finished goods warehouse by AGVs or forklifts, awaiting dispatch.

Core Systems & Technical Highlights

Intelligent Control System: Uses PLCs and industrial computers for central control, enabling coordinated operation and data monitoring of the entire line. Operators can easily set production parameters, stacking patterns, and packaging specifications via an HMI.

Machine Vision & Sensing Technology: Used for automatic panel quality inspection, dimension verification, and robot precise positioning, ensuring operational accuracy and consistency.

High-Precision Robotics: The robots used in stacking and packaging feature high speed, high repeatability positioning accuracy, and high reliability, capable of adapting to long-term continuous operation.

Modular & Flexible Design: The production line can be flexibly customized and expanded based on the customer's factory space, capacity requirements (e.g., annual output of 50,000 to 300,000 cubic meters), and product specifications.

Key Advantages & Value Proposition

Ultimate Efficiency Boost: Enables 24/7 continuous production, minimizes manual labor in stacking and packaging, significantly speeds up the production cycle, and markedly increases overall output capacity.

Significant Cost Reduction:

Labor Costs: Reduces reliance on extensive manual labor.

Quality Costs: Automated operations minimize damage like scratches and chipped edges caused by manual handling.

Management Costs: Simplifies production management processes.

Guaranteed Product Quality & Consistency: Mechanical stacking and packaging ensure every stack is uniform in appearance and structure, enhancing brand image and customer satisfaction.

Enhanced Operational Safety: Frees workers from heavy, repetitive, and potentially hazardous tasks, greatly improving the working environment and reducing workplace accidents.

Enables Lean Management & Traceability: The system automatically records production data for each stack and links it to the label information, achieving full life-cycle traceability from raw material to finished product, meeting the requirements of modern smart factories.

What Are the Application Scenarios for Particleboard?

As an economical, eco-friendly, and stable substrate, particleboard has extremely wide applications, covering almost all areas that require panels:

1. Furniture Manufacturing (Core Application)

Panel Furniture: The core substrate for cabinet, wardrobe, TV cabinet, bookcase, office partition, etc. When laminated with melamine-impregnated paper, it becomes the common "Melamine Board" or "Decorative Laminate," ready for furniture production.

Kitchen Furniture: Used for cabinet carcases and doors (especially after laminating or painting).

Office Furniture: Office desks, filing cabinets, conference tables.

2. Construction & Interior Decoration

Floor Underlayment: Serves as a subfloor under hardwood or laminate flooring, providing leveling, stability, and sound insulation.

Partitions & Ceilings: Used for internal non-load-bearing walls and ceiling materials.

Door Core: Acts as the internal filler for solid wood composite doors, reducing weight while ensuring flatness and strength.

3. Customized Home Furnishings & Display Industry

Whole Home Customization: A mainstream material in the whole home customization industry due to its excellent processability and customizability.

Store Displays: Used for shelves, display stands, and feature walls in malls and boutiques, offering cost control and easy surface decoration.

4. Other Industrial Applications

Kitchen & Bathroom Fixtures: Moisture-resistant particleboard is used for vanities in humid environments.

Tabletops & Work Surfaces: Thickened or specially treated particleboard can be used as a substrate for desks, bar counters, etc.

Packaging Cases: Used for making heavy-duty packaging cases or pallets.

Audio Equipment: Some speaker enclosures use high-density particleboard.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com