Please Choose Your Language

Please Choose Your Language

| Availability: | |

|---|---|

MH-OSB

MINGHUNG

The high-capacity and high-efficiency OSB production line is a modern manufacturing system designed with the core objectives of continuous operation, maximized output, optimized energy efficiency, and stable, high-quality production. It represents an industrial upgrade in OSB manufacturing through high automation, precise process control, and integrated intelligent material handling.

Key Performance Characteristics

High Capacity: Annual designed capacity for a single line can reach 300,000 to 600,000 cubic meters (depending on continuous press specifications and product thickness), far surpassing traditional multi-opening press lines (typically 100,000-250,000 m³/year).

High Efficiency:

Extremely fast production speed: Continuous press line speed can reach 40-120 meters per minute (depending on panel thickness).

Near-zero non-production time: Eliminates the cyclical interruptions for loading, unloading, and press opening/closing inherent to multi-opening presses.

High operational availability: Designed operational rate often exceeds 90%.

High Quality and Stability:

The continuous, constant hot-pressing process ensures exceptionally uniform physical properties along and across the panel.

Precise thickness control (tolerance can be within ±0.15mm).

Excellent surface flatness, requiring minimal sanding allowance, leading to high raw material utilization.

High Energy Efficiency and Low Consumption:

High thermal efficiency of the continuous press reduces energy consumption per unit product by 15-30% compared to intermittent presses.

High utilization rate of adhesives (especially MDI), with application rates capable of precise optimization.

High automation significantly reduces labor cost per unit product.

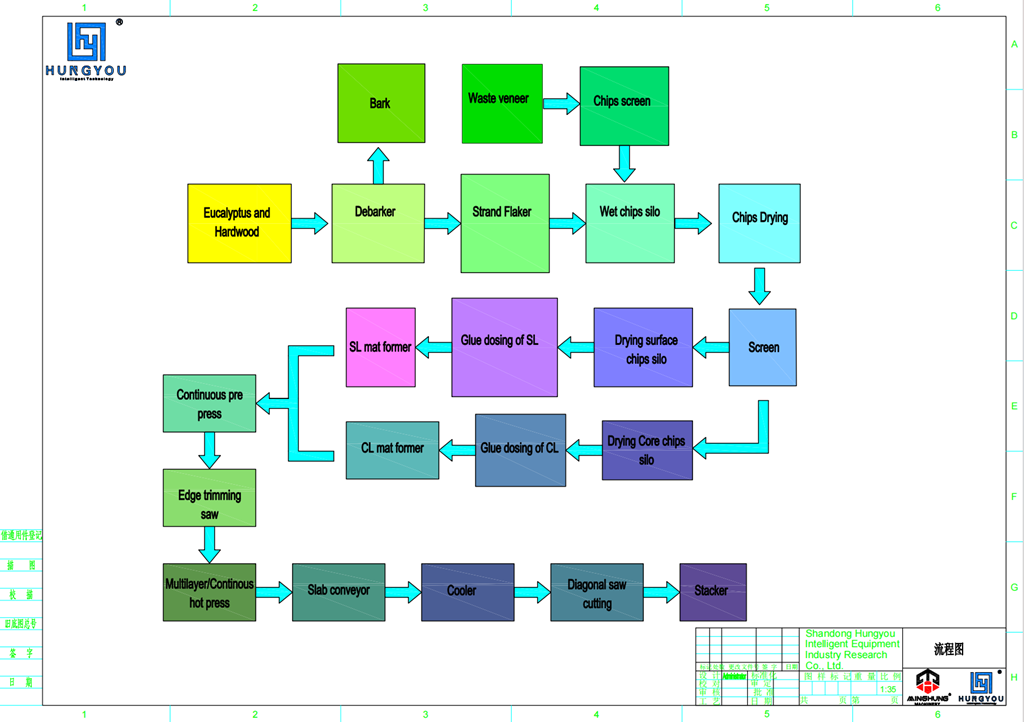

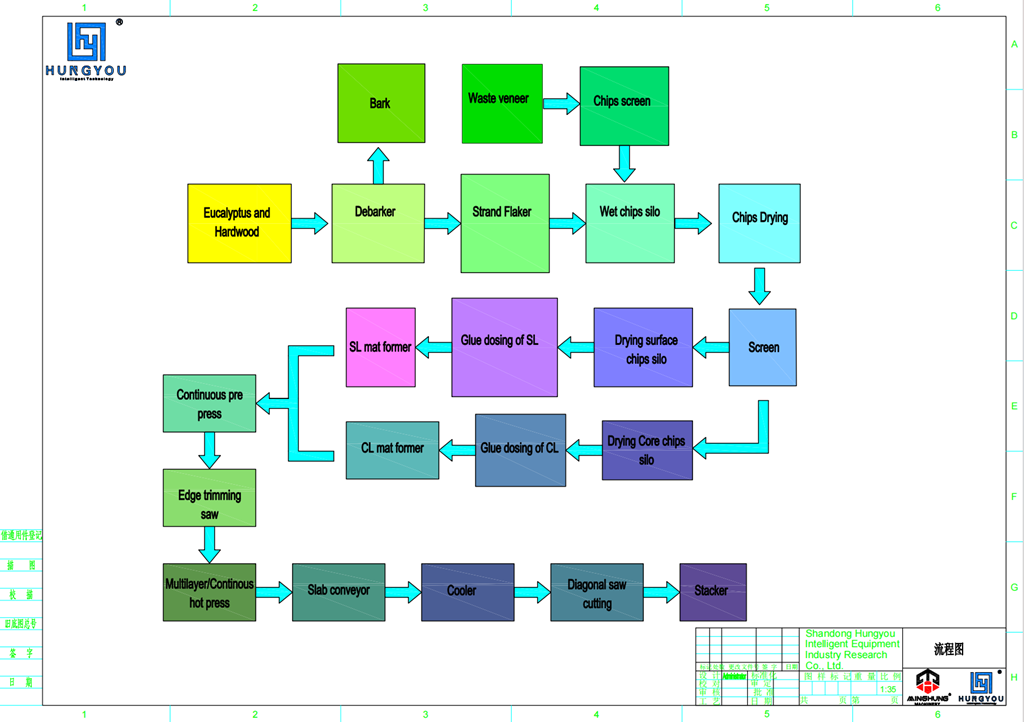

Raw material (small-diameter logs, wood chips) → Flaking → Drying → Screening/Sorting → Blending → Multi-Layer Oriented Forming → Continuous Flat Press Hot Pressing → Cooling → Trimming → Sanding → Grading & Packaging. Among these, mat forming and continuous hot pressing are the core processes enabling high capacity and efficiency.

Production Equipment

1. Raw Material Handling & Preparation Equipment

Log Debarker

Drum or Disc Chipper

Flaker (Ring or Drum Type)

Chip/Strand Screening and Sorting System (Vibrating Screens, Air Classifiers)

Wet Strand Storage Silo and Conveying System

chipper

cylindrical sieve

2. Drying Section Equipment

Rotary Drum Dryer (Triple-pass or Single-pass)

Hot Air Furnace System (Gas, Oil, or Biomass Fuel)

Dried Strand Screening and Conveying System

Dry Strand Storage Silos

3. Blending & Resin Supply System

Dry Strand Weighing Scales

High-Speed Rotary Blender

Resin Storage and Supply System (for MDI/PF/PMDI)

Wax Emulsion and Other Additive Supply Systems

Blended Strand Holding Bin

4. Forming Section Equipment (Core Area 1)

Strand Metering and Distribution System

High-Intensity Oriented Former (Mechanical or Pneumatic, Multi-Layer Capable)

Mat Pre-press (Belt or Roller Type)

Online Mat Weighing and Density Profiling System

Edge Trimming and Scrap Mat Recycling System

5. Hot Pressing Section Equipment (Core Area 2)

Continuous Flat Press or Multi-Opening Hot Press

Steel Belt and Drive System

Heating Platens and Hydraulic System

Online Thickness Gauging and Servo Control System

Press Infeed Forming Belt and Acceleration System

Press Outfeed Transfer System

6. Post-Press & Cutting Equipment

Star Cooler or Roller Cooling System

Longitudinal Trimming Saws

Cross-Cut Saws

Panel Stacking/De-stacking System

Intermediate Storage and Conditioning Area

7. Sanding & Finishing Equipment

Wide-Belt Sander (4-head, 6-head, or 8-head configuration)

Dust Extraction and Sander Dust Recovery System

Panel Grading and Inspection Station

Automatic Packaging and Stretch Wrapping System

Finished Product Storage and Dispatch System

8. Auxiliary & Utility Systems

Electrical Control System (PLC/DCS, Central Control Room)

Hydraulic and Pneumatic Power Packs

Thermal Energy Center (Thermal Oil Heater / Steam Boiler)

Environmental Protection Systems (Baghouse Filters, VOC Abatement, Water Treatment)

Compressed Air Station and Chilled Water System

1. Working Principle

The continuous flat press employs a steel belt conveying system to feed the formed and pre-pressed continuous mat into a long (often tens of meters) heating and pressing zone formed by upper and lower sets of heated platens. Carried by the steel belts at a constant speed, the mat undergoes continuous resin curing under set temperature, pressure, and thickness control, transforming from a loose mat at the infeed to a solid, continuous panel strip at the outfeed.

2. Core Structure and Subsystems

Steel Belt System:

High-Strength Alloy Steel Belts: Approximately 2-3mm thick, with special anti-adhesive coating (e.g., PTFE), resistant to high temperature, wear, and fatigue.

Drive and Tensioning System: Main drive rollers provide power; tension rollers maintain constant belt tension for smooth, slip-free operation.

Steering System: Monitors and corrects belt misalignment in real-time, critical for safe continuous operation.

Heated Platen System:

Zoned Heating Platens: The press is divided lengthwise into multiple pressure/temperature zones (e.g., preheating, main pressing, calibrating zones), each independently temperature-controlled (commonly using thermal oil, precise to ±1°C).

Hydraulic System: Utilizes a matrix of numerous (often hundreds) small hydraulic cylinders mounted on the platens. A hydraulic servo system enables continuous, precise local pressure adjustment for panel thickness control, which is the core technology for achieving high thickness accuracy.

Thickness Control System:

Online Thickness Gauge: Scans panel thickness in real-time at the press exit.

Closed-Loop Control: Thickness data is fed back to the hydraulic servo system, which continuously adjusts the pressure of corresponding cylinders to compensate for thickness deviations caused by variations in strand geometry, moisture content, or mat density.

Infeed and Outfeed Systems:

Infeed Sealing and Pressure Transition Zone: Prevents premature resin cure ("pre-cure") at mat edges and ensures a smooth pressure transition.

Outfeed Cooling and Tension Zone: Allows initial panel stabilization and maintains stable belt run.

Advantages Compared to Multi-Opening Presses

Feature | Continuous Flat Press | Traditional Multi-Opening Press |

Production Mode | True continuous production, no interruption | Intermittent cyclic production (load-press-unload) |

Capacity | Extremely high, determined by linear speed | Lower, limited by cycle time and number of openings |

Product Quality | Uniform longitudinal properties, very high thickness accuracy | Possible property variation between openings |

Panel Dimensions | Unlimited length, flexible cutting | Fixed by platen size |

Energy Consumption | High thermal efficiency, lower energy per unit | Significant heat loss due to frequent opening/closing |

Automation | Fully integrated into continuous automated line | Requires complex loading/unloading systems |

Flexibility | Ideal for high-volume, single or similar thickness products | Relatively more flexible for changing thickness specifications |

If interested please contact us for a quote.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com

The high-capacity and high-efficiency OSB production line is a modern manufacturing system designed with the core objectives of continuous operation, maximized output, optimized energy efficiency, and stable, high-quality production. It represents an industrial upgrade in OSB manufacturing through high automation, precise process control, and integrated intelligent material handling.

Key Performance Characteristics

High Capacity: Annual designed capacity for a single line can reach 300,000 to 600,000 cubic meters (depending on continuous press specifications and product thickness), far surpassing traditional multi-opening press lines (typically 100,000-250,000 m³/year).

High Efficiency:

Extremely fast production speed: Continuous press line speed can reach 40-120 meters per minute (depending on panel thickness).

Near-zero non-production time: Eliminates the cyclical interruptions for loading, unloading, and press opening/closing inherent to multi-opening presses.

High operational availability: Designed operational rate often exceeds 90%.

High Quality and Stability:

The continuous, constant hot-pressing process ensures exceptionally uniform physical properties along and across the panel.

Precise thickness control (tolerance can be within ±0.15mm).

Excellent surface flatness, requiring minimal sanding allowance, leading to high raw material utilization.

High Energy Efficiency and Low Consumption:

High thermal efficiency of the continuous press reduces energy consumption per unit product by 15-30% compared to intermittent presses.

High utilization rate of adhesives (especially MDI), with application rates capable of precise optimization.

High automation significantly reduces labor cost per unit product.

Raw material (small-diameter logs, wood chips) → Flaking → Drying → Screening/Sorting → Blending → Multi-Layer Oriented Forming → Continuous Flat Press Hot Pressing → Cooling → Trimming → Sanding → Grading & Packaging. Among these, mat forming and continuous hot pressing are the core processes enabling high capacity and efficiency.

Production Equipment

1. Raw Material Handling & Preparation Equipment

Log Debarker

Drum or Disc Chipper

Flaker (Ring or Drum Type)

Chip/Strand Screening and Sorting System (Vibrating Screens, Air Classifiers)

Wet Strand Storage Silo and Conveying System

chipper

cylindrical sieve

2. Drying Section Equipment

Rotary Drum Dryer (Triple-pass or Single-pass)

Hot Air Furnace System (Gas, Oil, or Biomass Fuel)

Dried Strand Screening and Conveying System

Dry Strand Storage Silos

3. Blending & Resin Supply System

Dry Strand Weighing Scales

High-Speed Rotary Blender

Resin Storage and Supply System (for MDI/PF/PMDI)

Wax Emulsion and Other Additive Supply Systems

Blended Strand Holding Bin

4. Forming Section Equipment (Core Area 1)

Strand Metering and Distribution System

High-Intensity Oriented Former (Mechanical or Pneumatic, Multi-Layer Capable)

Mat Pre-press (Belt or Roller Type)

Online Mat Weighing and Density Profiling System

Edge Trimming and Scrap Mat Recycling System

5. Hot Pressing Section Equipment (Core Area 2)

Continuous Flat Press or Multi-Opening Hot Press

Steel Belt and Drive System

Heating Platens and Hydraulic System

Online Thickness Gauging and Servo Control System

Press Infeed Forming Belt and Acceleration System

Press Outfeed Transfer System

6. Post-Press & Cutting Equipment

Star Cooler or Roller Cooling System

Longitudinal Trimming Saws

Cross-Cut Saws

Panel Stacking/De-stacking System

Intermediate Storage and Conditioning Area

7. Sanding & Finishing Equipment

Wide-Belt Sander (4-head, 6-head, or 8-head configuration)

Dust Extraction and Sander Dust Recovery System

Panel Grading and Inspection Station

Automatic Packaging and Stretch Wrapping System

Finished Product Storage and Dispatch System

8. Auxiliary & Utility Systems

Electrical Control System (PLC/DCS, Central Control Room)

Hydraulic and Pneumatic Power Packs

Thermal Energy Center (Thermal Oil Heater / Steam Boiler)

Environmental Protection Systems (Baghouse Filters, VOC Abatement, Water Treatment)

Compressed Air Station and Chilled Water System

1. Working Principle

The continuous flat press employs a steel belt conveying system to feed the formed and pre-pressed continuous mat into a long (often tens of meters) heating and pressing zone formed by upper and lower sets of heated platens. Carried by the steel belts at a constant speed, the mat undergoes continuous resin curing under set temperature, pressure, and thickness control, transforming from a loose mat at the infeed to a solid, continuous panel strip at the outfeed.

2. Core Structure and Subsystems

Steel Belt System:

High-Strength Alloy Steel Belts: Approximately 2-3mm thick, with special anti-adhesive coating (e.g., PTFE), resistant to high temperature, wear, and fatigue.

Drive and Tensioning System: Main drive rollers provide power; tension rollers maintain constant belt tension for smooth, slip-free operation.

Steering System: Monitors and corrects belt misalignment in real-time, critical for safe continuous operation.

Heated Platen System:

Zoned Heating Platens: The press is divided lengthwise into multiple pressure/temperature zones (e.g., preheating, main pressing, calibrating zones), each independently temperature-controlled (commonly using thermal oil, precise to ±1°C).

Hydraulic System: Utilizes a matrix of numerous (often hundreds) small hydraulic cylinders mounted on the platens. A hydraulic servo system enables continuous, precise local pressure adjustment for panel thickness control, which is the core technology for achieving high thickness accuracy.

Thickness Control System:

Online Thickness Gauge: Scans panel thickness in real-time at the press exit.

Closed-Loop Control: Thickness data is fed back to the hydraulic servo system, which continuously adjusts the pressure of corresponding cylinders to compensate for thickness deviations caused by variations in strand geometry, moisture content, or mat density.

Infeed and Outfeed Systems:

Infeed Sealing and Pressure Transition Zone: Prevents premature resin cure ("pre-cure") at mat edges and ensures a smooth pressure transition.

Outfeed Cooling and Tension Zone: Allows initial panel stabilization and maintains stable belt run.

Advantages Compared to Multi-Opening Presses

Feature | Continuous Flat Press | Traditional Multi-Opening Press |

Production Mode | True continuous production, no interruption | Intermittent cyclic production (load-press-unload) |

Capacity | Extremely high, determined by linear speed | Lower, limited by cycle time and number of openings |

Product Quality | Uniform longitudinal properties, very high thickness accuracy | Possible property variation between openings |

Panel Dimensions | Unlimited length, flexible cutting | Fixed by platen size |

Energy Consumption | High thermal efficiency, lower energy per unit | Significant heat loss due to frequent opening/closing |

Automation | Fully integrated into continuous automated line | Requires complex loading/unloading systems |

Flexibility | Ideal for high-volume, single or similar thickness products | Relatively more flexible for changing thickness specifications |

If interested please contact us for a quote.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com