Please Choose Your Language

Please Choose Your Language

| Availability: | |

|---|---|

MH-OSB

MINGHUNG

|

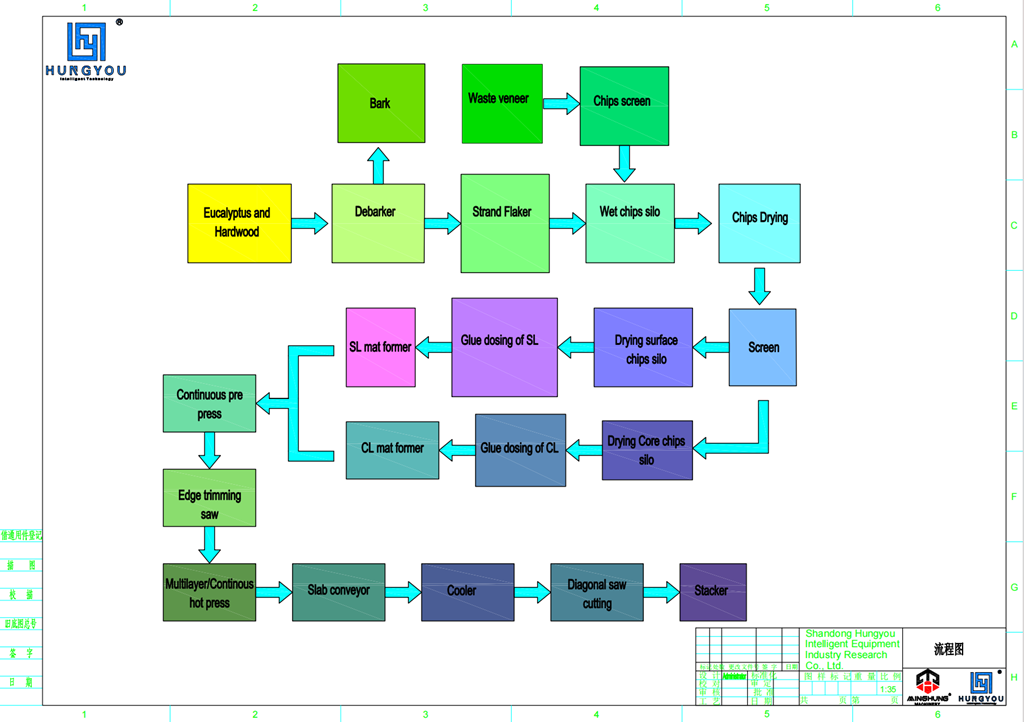

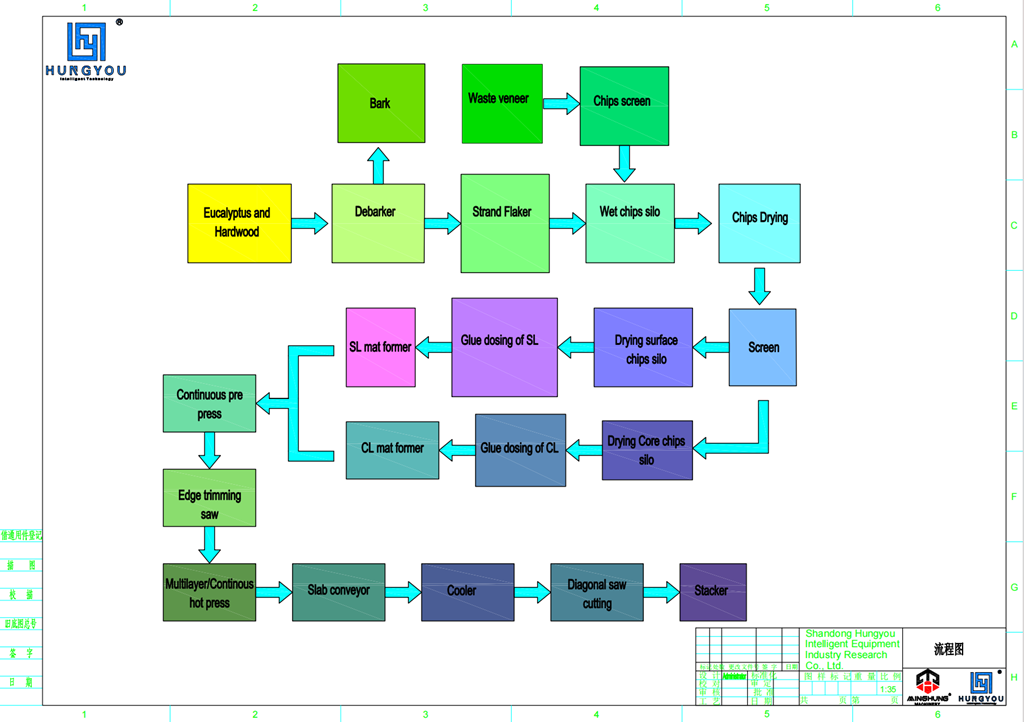

OSB Panel Production Line Process

A complete OSB production line consists of the following main stages:

1. Log Processing: Debarking, washing, and cutting into blocks.

2. Strand Preparation: Flaking wood blocks into strands of specified dimensions.

3. Drying: Reducing strand moisture content to process requirements.

4. Screening and Sorting: Grading by size and removing impurities.

5. Blending: Precisely applying resin binder (typically MDI or Phenol-Formaldehyde).

6. Oriented Forming: The core process, layering resinated strands directionally into a mat.

7. Pre-pressing and Hot Pressing: Curing under high temperature and pressure in a continuous or batch press.

8. Cooling and Conditioning: Reducing temperature and releasing internal stress.

9. Trimming and Sanding: Cutting to size and surface finishing.

10. Inspection and Packaging: Quality checking and packaging for storage.

|

Production Equipment

I. Raw Material Preparation Section Equipment

1. Chipping and Flaking Equipment

Drum Chipper: Processes logs or wood blocks into required wood chips

Ring Flaker: Core equipment that flakes wood chips into standard geometric strands (typically 40-150mm in length)

Equipped with hydraulic drive system, blade angle precisely adjustable

Production capacity: 10-100 m³/hour (oven-dry basis)

Acceptable strand yield can exceed 90%

2. Screening and Sorting System

Multi-deck Vibrating Screen: Grades strands by size (surface fines, core coarse material)

Air Classifier: Removes impurities, bark, and dust

Chip Storage Bin and Strand Storage Bin: Equipped with level monitoring and automatic feeding/discharging systems

II. Drying and Blending Section Equipment

1. Drying System

Triple-pass Rotary Drum Dryer (Mainstream equipment)

Heat source: Natural gas, biomass fuel, or thermal oil

Drying temperature: Adjustable between 200-400°C

Moisture content after drying: 2-4%

Equipped with exhaust heat recovery and dust removal systems

2. Blending System

High-speed Rotary Blender

Dual-shaft or multi-shaft design for uniform blending

Resin application control accuracy: ±0.5%

Resin compatibility: MDI, PF, PMDI, etc.

Capable of adding additives like wax, curing agents

Resin Preparation and Supply System

Automatic metering, mixing, and delivery

Precise temperature control (MDI requires constant temperature storage)

III. Forming and Mat Forming Section Equipment

1. High-Intensity Oriented Former (Core Equipment)

Mechanical Oriented Former

Working Principle: Orients strands through centrifugal force generated by high-speed rotating discs

Core Components:

Metering bins: Precisely control strand flow for each layer

Orienting discs: Adjustable speed (200-800 rpm), high orientation accuracy

Forming heads: Independently controlled multi-layer system, up to 5 layers

Scanning system: Real-time mat density profile monitoring

Pneumatic Oriented Former

Orients strands through high-velocity air flow fields

Suitable for extra-long thin strands (length >100mm)

Gentler orientation with minimal strand damage

Technical Parameters:

Forming speed: Up to 60 m/min

Forming width: 1300-2800 mm

Thickness control accuracy: ±0.1 mm

Density deviation: <±3%

2. Mat Pre-press

Continuous Belt Pre-press

Initial compaction for easier transport

Pre-press pressure: 2-8 MPa

Equipped with edge trimming and scrap recovery systems

IV. Hot Pressing and Post-processing Section Equipment

1. Hot Pressing System

Continuous Flat Press

Pressure: 200-500 N/cm²

Temperature: 180-240°C (adjustable according to resin type)

Press length: 15-50 meters (determines production speed)

Panel width: 1.3-2.8 meters

Technical Features:

Steel belt system: Special coating, anti-stick, long service life

Heating system: Thermal oil or steam heated platens

Thickness control system: Online thickness gauge + servo cylinders

Production speed: Up to 100 m/min

2. Cooling and Conditioning System

Star Cooler:

Cools panels from high temperature to below 50°C

Cooling time: 20-60 minutes

Equipped with forced air cooling system

Conditioning Warehouse:

Constant temperature and humidity environment (20-30°C, 45-65% RH)

Conditioning time: 24-72 hours

Automated stacking and transport system

V. Cutting and Sanding Section Equipment

1. Trimming Saws

High-speed Edge Trimming System:

Dual saw blade design for simultaneous edge trimming

Cutting accuracy: ±0.5 mm

Automatic scrap shredding and recovery

Cross-cut Saw:

Flying saw or push-table saw design

Programmable length cutting (up to 6 meters)

Production capacity: 30-100 panels/minute

2. Sander

Number of sanding heads: 4-8 (combination of coarse and fine sanding)

Sanding belt width: 1300-2800 mm

Thickness tolerance after sanding: ±0.1 mm

Equipped with automatic thickness detection and compensation system

Dust collection efficiency: >99.9%

VI. Auxiliary and Control Systems

1. Automation Control System

Central Control Room:

PLC control system: Siemens, AB, etc.

DCS distributed control system

Online quality monitoring:

Thickness gauge (radiation or laser)

Density profile scanner

Online moisture detector

Defect detection system (X-ray or vision recognition)

2. Energy and Environmental Protection Systems

Thermal Energy Center:

Thermal oil heater or steam boiler

Flue gas heat recovery system

Biomass combustion system (optional)

Environmental Treatment System:

Baghouse filter: Dust removal efficiency >99.5%

VOC treatment system: RTO or activated carbon adsorption

Water circulation system: Zero discharge design

|

Advantages of this production line

Superior Product Performance: The oriented structure enhances OSB's mechanical properties (especially bending strength and internal bond) by 50%-100% compared to standard particleboard, allowing it to partially replace plywood.

High Raw Material Utilization: Can use fast-growing species, small-diameter logs, thinnings, and wood processing residues, reducing raw material costs.

High Production Efficiency: Continuous, automated operation with an annual capacity ranging from 200,000 to 500,000 cubic meters (depending on line configuration).

Energy Saving & Eco-Friendly: Incorporates high-efficiency drying and heat recovery systems to reduce energy consumption. Uses environmentally friendly MDI resin (no-added formaldehyde), enabling production of E0 or CARB-certified panels.

Production Flexibility: A single line can produce various OSB specifications (thickness: 6-40mm) for multiple applications (structural, decorative, packaging) by adjusting forming parameters.

High Level of Automation: Enables full-process data monitoring and quality traceability from raw material to finished product, reducing labor dependency and improving consistency.

|

Application of OSB Panels

Building & Construction: Wall sheathing, roof decking, floor underlayment, I-joist webs, etc. A primary material for light-frame wood construction.

Packaging & Logistics: Heavy-duty crates, pallets, warehouse dunnage due to high strength and impact resistance.

Furniture Manufacturing: Cabinet carcasses, tabletop cores, drawer bottoms.

Interior Decoration: Substrate for wall and ceiling finishes.

Specialty Applications: Container flooring, RV floors, structural panels for temporary exhibition booths.

|

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com

|

OSB Panel Production Line Process

A complete OSB production line consists of the following main stages:

1. Log Processing: Debarking, washing, and cutting into blocks.

2. Strand Preparation: Flaking wood blocks into strands of specified dimensions.

3. Drying: Reducing strand moisture content to process requirements.

4. Screening and Sorting: Grading by size and removing impurities.

5. Blending: Precisely applying resin binder (typically MDI or Phenol-Formaldehyde).

6. Oriented Forming: The core process, layering resinated strands directionally into a mat.

7. Pre-pressing and Hot Pressing: Curing under high temperature and pressure in a continuous or batch press.

8. Cooling and Conditioning: Reducing temperature and releasing internal stress.

9. Trimming and Sanding: Cutting to size and surface finishing.

10. Inspection and Packaging: Quality checking and packaging for storage.

|

Production Equipment

I. Raw Material Preparation Section Equipment

1. Chipping and Flaking Equipment

Drum Chipper: Processes logs or wood blocks into required wood chips

Ring Flaker: Core equipment that flakes wood chips into standard geometric strands (typically 40-150mm in length)

Equipped with hydraulic drive system, blade angle precisely adjustable

Production capacity: 10-100 m³/hour (oven-dry basis)

Acceptable strand yield can exceed 90%

2. Screening and Sorting System

Multi-deck Vibrating Screen: Grades strands by size (surface fines, core coarse material)

Air Classifier: Removes impurities, bark, and dust

Chip Storage Bin and Strand Storage Bin: Equipped with level monitoring and automatic feeding/discharging systems

II. Drying and Blending Section Equipment

1. Drying System

Triple-pass Rotary Drum Dryer (Mainstream equipment)

Heat source: Natural gas, biomass fuel, or thermal oil

Drying temperature: Adjustable between 200-400°C

Moisture content after drying: 2-4%

Equipped with exhaust heat recovery and dust removal systems

2. Blending System

High-speed Rotary Blender

Dual-shaft or multi-shaft design for uniform blending

Resin application control accuracy: ±0.5%

Resin compatibility: MDI, PF, PMDI, etc.

Capable of adding additives like wax, curing agents

Resin Preparation and Supply System

Automatic metering, mixing, and delivery

Precise temperature control (MDI requires constant temperature storage)

III. Forming and Mat Forming Section Equipment

1. High-Intensity Oriented Former (Core Equipment)

Mechanical Oriented Former

Working Principle: Orients strands through centrifugal force generated by high-speed rotating discs

Core Components:

Metering bins: Precisely control strand flow for each layer

Orienting discs: Adjustable speed (200-800 rpm), high orientation accuracy

Forming heads: Independently controlled multi-layer system, up to 5 layers

Scanning system: Real-time mat density profile monitoring

Pneumatic Oriented Former

Orients strands through high-velocity air flow fields

Suitable for extra-long thin strands (length >100mm)

Gentler orientation with minimal strand damage

Technical Parameters:

Forming speed: Up to 60 m/min

Forming width: 1300-2800 mm

Thickness control accuracy: ±0.1 mm

Density deviation: <±3%

2. Mat Pre-press

Continuous Belt Pre-press

Initial compaction for easier transport

Pre-press pressure: 2-8 MPa

Equipped with edge trimming and scrap recovery systems

IV. Hot Pressing and Post-processing Section Equipment

1. Hot Pressing System

Continuous Flat Press

Pressure: 200-500 N/cm²

Temperature: 180-240°C (adjustable according to resin type)

Press length: 15-50 meters (determines production speed)

Panel width: 1.3-2.8 meters

Technical Features:

Steel belt system: Special coating, anti-stick, long service life

Heating system: Thermal oil or steam heated platens

Thickness control system: Online thickness gauge + servo cylinders

Production speed: Up to 100 m/min

2. Cooling and Conditioning System

Star Cooler:

Cools panels from high temperature to below 50°C

Cooling time: 20-60 minutes

Equipped with forced air cooling system

Conditioning Warehouse:

Constant temperature and humidity environment (20-30°C, 45-65% RH)

Conditioning time: 24-72 hours

Automated stacking and transport system

V. Cutting and Sanding Section Equipment

1. Trimming Saws

High-speed Edge Trimming System:

Dual saw blade design for simultaneous edge trimming

Cutting accuracy: ±0.5 mm

Automatic scrap shredding and recovery

Cross-cut Saw:

Flying saw or push-table saw design

Programmable length cutting (up to 6 meters)

Production capacity: 30-100 panels/minute

2. Sander

Number of sanding heads: 4-8 (combination of coarse and fine sanding)

Sanding belt width: 1300-2800 mm

Thickness tolerance after sanding: ±0.1 mm

Equipped with automatic thickness detection and compensation system

Dust collection efficiency: >99.9%

VI. Auxiliary and Control Systems

1. Automation Control System

Central Control Room:

PLC control system: Siemens, AB, etc.

DCS distributed control system

Online quality monitoring:

Thickness gauge (radiation or laser)

Density profile scanner

Online moisture detector

Defect detection system (X-ray or vision recognition)

2. Energy and Environmental Protection Systems

Thermal Energy Center:

Thermal oil heater or steam boiler

Flue gas heat recovery system

Biomass combustion system (optional)

Environmental Treatment System:

Baghouse filter: Dust removal efficiency >99.5%

VOC treatment system: RTO or activated carbon adsorption

Water circulation system: Zero discharge design

|

Advantages of this production line

Superior Product Performance: The oriented structure enhances OSB's mechanical properties (especially bending strength and internal bond) by 50%-100% compared to standard particleboard, allowing it to partially replace plywood.

High Raw Material Utilization: Can use fast-growing species, small-diameter logs, thinnings, and wood processing residues, reducing raw material costs.

High Production Efficiency: Continuous, automated operation with an annual capacity ranging from 200,000 to 500,000 cubic meters (depending on line configuration).

Energy Saving & Eco-Friendly: Incorporates high-efficiency drying and heat recovery systems to reduce energy consumption. Uses environmentally friendly MDI resin (no-added formaldehyde), enabling production of E0 or CARB-certified panels.

Production Flexibility: A single line can produce various OSB specifications (thickness: 6-40mm) for multiple applications (structural, decorative, packaging) by adjusting forming parameters.

High Level of Automation: Enables full-process data monitoring and quality traceability from raw material to finished product, reducing labor dependency and improving consistency.

|

Application of OSB Panels

Building & Construction: Wall sheathing, roof decking, floor underlayment, I-joist webs, etc. A primary material for light-frame wood construction.

Packaging & Logistics: Heavy-duty crates, pallets, warehouse dunnage due to high strength and impact resistance.

Furniture Manufacturing: Cabinet carcasses, tabletop cores, drawer bottoms.

Interior Decoration: Substrate for wall and ceiling finishes.

Specialty Applications: Container flooring, RV floors, structural panels for temporary exhibition booths.

|

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com