Please Choose Your Language

Please Choose Your Language

| Availability: | |

|---|---|

MH

MINGHUNG

Plywood Production Equipment

1. Raw Material Processing Equipment

Debarker | Bucking Saw |

Function: Remove bark from logs to ensure clean wood surface Types: Ring debarker, Drum debarker Features: High-efficiency peeling, reduced tool wear | Function: Cut logs into required lengths Types: Chain saw type, Circular saw type Precision: ±1mm length error |

|  |

Steaming Equipment

Function: Soften wood for easier peeling

Capacity: 10-50 m³

Temperature range: 40-80℃

2. Peeling and Drying Equipment

Peeling Lathe | Dryer |

Types: Spindle lathe (for large diameter logs) Spindleless lathe (for small diameter logs) Precision: ±0.05mm thickness error Capacity: 100-300 sheets/hour | Types: Roller dryer Mesh belt dryer Temperature precision: ±2℃ Drying capacity: 5-20 tons/hour |

|  |

3. Gluing and Layup Equipment

Glue Spreader |

Types: Four-roll spreader Two-roll spreader Spreading precision: ±5g/m² Adhesive compatibility: UF, PF, MUF glue |

|

Layup Line

Automation level: Full/semi-automatic

Alignment precision: ±0.5mm

Capacity: 200-600 sheets/hour

4. Pressing Equipment

Pre-press | Hot Press |

Pressure: 100-300 tons Holding time: 5-15 minutes Function: Preliminary shaping for easier loading | Openings: 10-30 layers Platen size: 4'×8' to 6'×12' Maximum temperature: 200℃ Pressure control precision: ±2% |

|  |

5. Finishing Equipment

Sanding Machine | Trimming Saw |

Types: Wide belt sander Double-sided calibrating sander Sanding precision: ±0.1mm Capacity: 30-60 sheets/hour | Types: Cross-cut and edge trim combination saw CNC trimming center Cutting precision: ±0.2mm Maximum working width: 2.5m |

|  |

6. Auxiliary Systems

Glue Mixing System | Dust Collection System |

Capacity: 1-10 tons Mixing speed: 20-60rpm Metering precision: ±0.5% | Air volume: 10000-50000 m³/h Filtration efficiency: 99.9% Noise control: <85dB |

Key Technical Features:

1. Automation Level: PLC control with touch screen interface

2. Energy Efficiency: Heat recovery systems reduce energy consumption by 20-30%

3. Safety Standards: CE certification with emergency stop systems

4. Maintenance: Easy-access design with modular components

5. Flexibility: Adjustable parameters for different product specifications

Multi-Opening Hot Press

I. Equipment Overview

The multi-opening hot press is a core equipment in the production of artificial board such as plywood, particleboard, and fiberboard. It uses hot-press to bond and cure panel blanks under high temperature and pressure. Featuring a multi-opening design (typically 10-30 openings), it can press multiple panels simultaneously, significantly improving production efficiency. Operating temperature ranges from 120-200℃, with working pressure reaching 200-300 tons.

II. Main Structural Components

1. Frame System

Four-column or frame-type structure

Load-bearing frame composed of upper/lower beams, columns, and nuts

Ensures stability and precision under high pressure

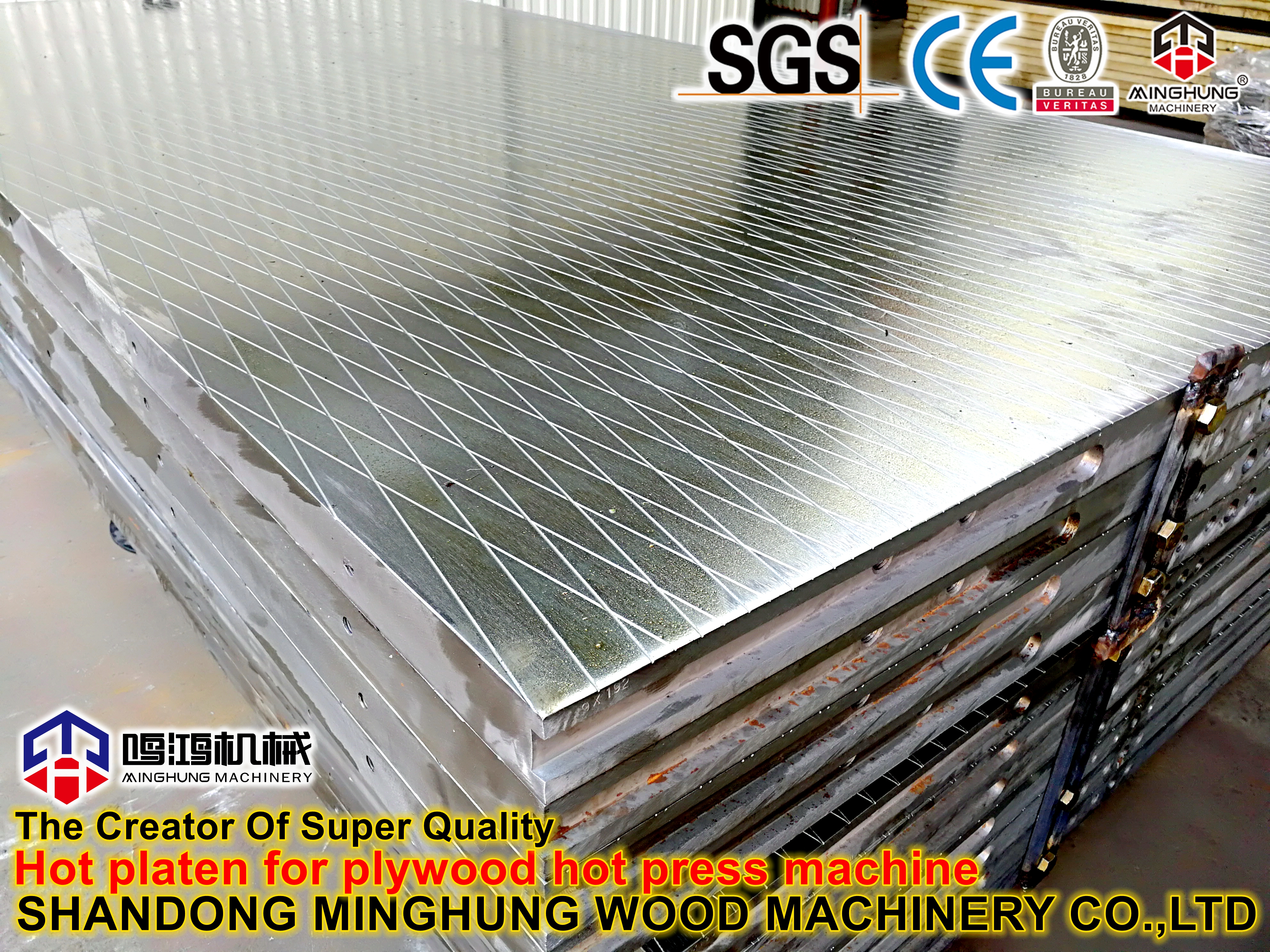

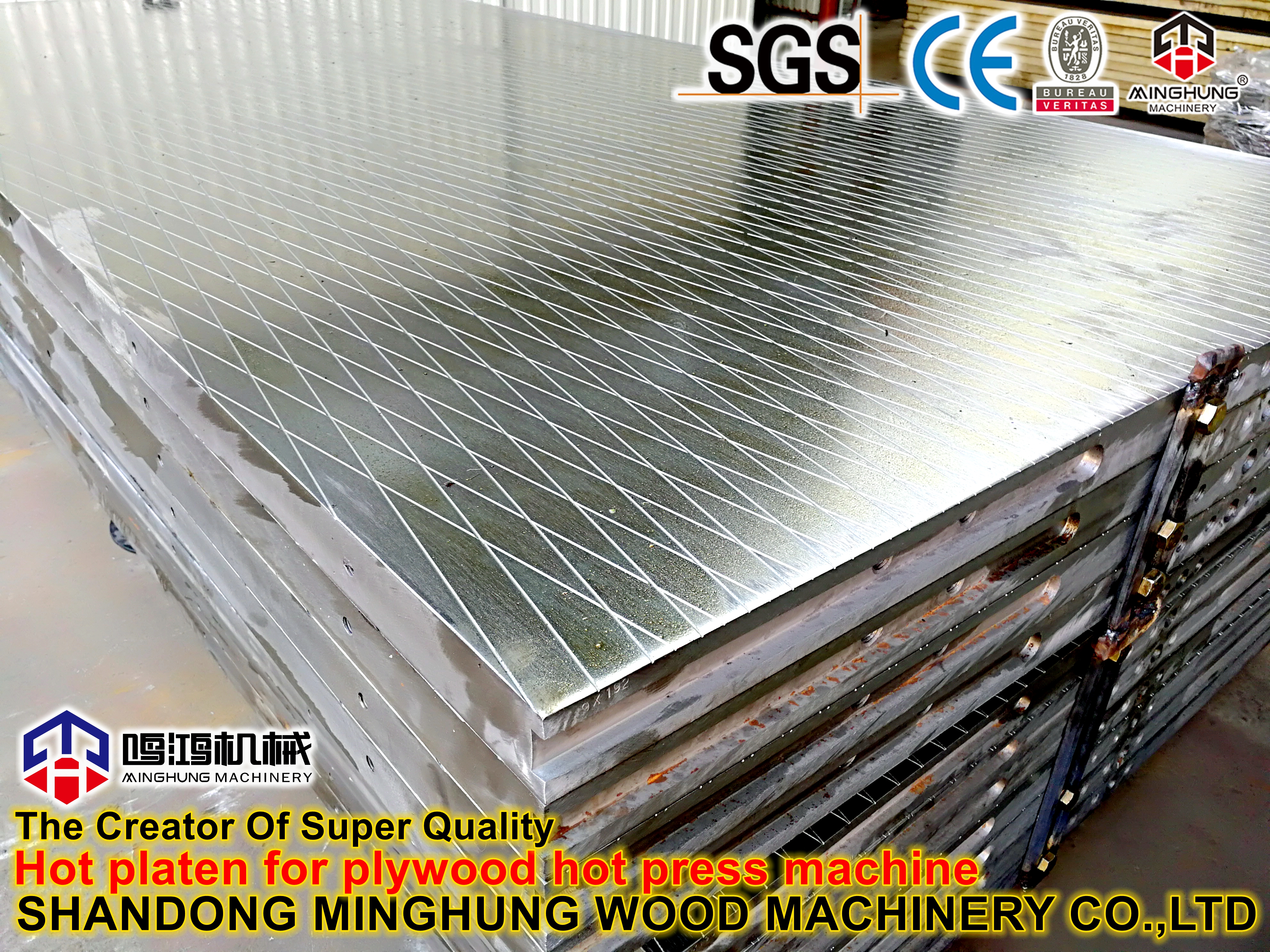

2. Hot Platen System

Made of high-quality alloy steel

Internally designed with uniformly distributed oil channels

Chrome-plated surface ensures temperature uniformity (±2℃ variation)

Standard sizes: 4'×8' (1220×2440mm) to 6'×12' (1830×3660mm)

3. Hydraulic System

Utilizes high-pressure, high-flow piston pumps

Working pressure: 20-30MPa

Equipped with accumulators for stable pressure

Precision pressure sensors with ±1% control accuracy

4. Heating System

Heat sources: steam, thermal oil, or electric heating

Temperature control accuracy: ±1℃

Zoned temperature control ensures platen temperature uniformity

Features rapid heating system

5. Control System

PLC + touchscreen intelligent control

Stores multiple process recipes

Real-time display of temperature, pressure, and time parameters

Fault self-diagnosis function

III. Work Process

1. Loading: Automatic loader feeds blanks between each hot platen

2. Closing: Press rapidly closes to set position

3. Pressing: Applies pressure according to preset curve

4. Pressure Holding: Maintains set temperature and pressure for specified time

5. Pressure Relief: Releases pressure in stages to prevent panel bursting

6. Opening: Platens open, automatic unloading

IV. Application Fields

1. Plywood production: Various construction formwork, furniture panels

2. Particleboard production: Furniture substrate, decorative substrate

3. Fiberboard production: Medium/high density fiberboard

4. Special panels: Fireproof boards, marine panels

V. Advantages

1. High production efficiency: Multi-opening design enables batch production

2. Excellent product quality: Precise temperature/pressure control ensures stable panel performance

3. High automation: Reduces manual operation and labor intensity

4. Low energy consumption: Features insulation design and heat recovery systems

5. Easy operation and maintenance: Modular design with low failure rate

Technical Specifications

Number of Openings: 10-30 layers

Max Pressure: 200-300 tons

Platen Size: 1220×2440mm to 1830×3660mm

Temperature Range: 120-200℃

Control Accuracy: Temperature ±1℃, Pressure ±1%

Heating Methods: Steam, Thermal Oil, Electric

Automation Level: Fully automatic with PLC control

Key Advantages

1. High-Quality Output: Uniform temperature and pressure distribution ensure consistent density and structural stability of plywood;

2. High Efficiency: Multi-opening design allows simultaneous pressing of multiple panels, while automation reduces manual intervention;

3. Energy Efficiency: Closed-loop heating and insulation design minimize energy consumption, complying with green production standards;

4. Intelligent Control: Integrated PLC and touchscreen interface enable real-time monitoring of temperature, pressure, and production data, supporting fault diagnosis and remote maintenance.

Request Your Plywood Solution Now! 3D plant layout, on-site commissioning & global spare parts – Dominate the premium board market today!

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com

Plywood Production Equipment

1. Raw Material Processing Equipment

Debarker | Bucking Saw |

Function: Remove bark from logs to ensure clean wood surface Types: Ring debarker, Drum debarker Features: High-efficiency peeling, reduced tool wear | Function: Cut logs into required lengths Types: Chain saw type, Circular saw type Precision: ±1mm length error |

|  |

Steaming Equipment

Function: Soften wood for easier peeling

Capacity: 10-50 m³

Temperature range: 40-80℃

2. Peeling and Drying Equipment

Peeling Lathe | Dryer |

Types: Spindle lathe (for large diameter logs) Spindleless lathe (for small diameter logs) Precision: ±0.05mm thickness error Capacity: 100-300 sheets/hour | Types: Roller dryer Mesh belt dryer Temperature precision: ±2℃ Drying capacity: 5-20 tons/hour |

|  |

3. Gluing and Layup Equipment

Glue Spreader |

Types: Four-roll spreader Two-roll spreader Spreading precision: ±5g/m² Adhesive compatibility: UF, PF, MUF glue |

|

Layup Line

Automation level: Full/semi-automatic

Alignment precision: ±0.5mm

Capacity: 200-600 sheets/hour

4. Pressing Equipment

Pre-press | Hot Press |

Pressure: 100-300 tons Holding time: 5-15 minutes Function: Preliminary shaping for easier loading | Openings: 10-30 layers Platen size: 4'×8' to 6'×12' Maximum temperature: 200℃ Pressure control precision: ±2% |

|  |

5. Finishing Equipment

Sanding Machine | Trimming Saw |

Types: Wide belt sander Double-sided calibrating sander Sanding precision: ±0.1mm Capacity: 30-60 sheets/hour | Types: Cross-cut and edge trim combination saw CNC trimming center Cutting precision: ±0.2mm Maximum working width: 2.5m |

|  |

6. Auxiliary Systems

Glue Mixing System | Dust Collection System |

Capacity: 1-10 tons Mixing speed: 20-60rpm Metering precision: ±0.5% | Air volume: 10000-50000 m³/h Filtration efficiency: 99.9% Noise control: <85dB |

Key Technical Features:

1. Automation Level: PLC control with touch screen interface

2. Energy Efficiency: Heat recovery systems reduce energy consumption by 20-30%

3. Safety Standards: CE certification with emergency stop systems

4. Maintenance: Easy-access design with modular components

5. Flexibility: Adjustable parameters for different product specifications

Multi-Opening Hot Press

I. Equipment Overview

The multi-opening hot press is a core equipment in the production of artificial board such as plywood, particleboard, and fiberboard. It uses hot-press to bond and cure panel blanks under high temperature and pressure. Featuring a multi-opening design (typically 10-30 openings), it can press multiple panels simultaneously, significantly improving production efficiency. Operating temperature ranges from 120-200℃, with working pressure reaching 200-300 tons.

II. Main Structural Components

1. Frame System

Four-column or frame-type structure

Load-bearing frame composed of upper/lower beams, columns, and nuts

Ensures stability and precision under high pressure

2. Hot Platen System

Made of high-quality alloy steel

Internally designed with uniformly distributed oil channels

Chrome-plated surface ensures temperature uniformity (±2℃ variation)

Standard sizes: 4'×8' (1220×2440mm) to 6'×12' (1830×3660mm)

3. Hydraulic System

Utilizes high-pressure, high-flow piston pumps

Working pressure: 20-30MPa

Equipped with accumulators for stable pressure

Precision pressure sensors with ±1% control accuracy

4. Heating System

Heat sources: steam, thermal oil, or electric heating

Temperature control accuracy: ±1℃

Zoned temperature control ensures platen temperature uniformity

Features rapid heating system

5. Control System

PLC + touchscreen intelligent control

Stores multiple process recipes

Real-time display of temperature, pressure, and time parameters

Fault self-diagnosis function

III. Work Process

1. Loading: Automatic loader feeds blanks between each hot platen

2. Closing: Press rapidly closes to set position

3. Pressing: Applies pressure according to preset curve

4. Pressure Holding: Maintains set temperature and pressure for specified time

5. Pressure Relief: Releases pressure in stages to prevent panel bursting

6. Opening: Platens open, automatic unloading

IV. Application Fields

1. Plywood production: Various construction formwork, furniture panels

2. Particleboard production: Furniture substrate, decorative substrate

3. Fiberboard production: Medium/high density fiberboard

4. Special panels: Fireproof boards, marine panels

V. Advantages

1. High production efficiency: Multi-opening design enables batch production

2. Excellent product quality: Precise temperature/pressure control ensures stable panel performance

3. High automation: Reduces manual operation and labor intensity

4. Low energy consumption: Features insulation design and heat recovery systems

5. Easy operation and maintenance: Modular design with low failure rate

Technical Specifications

Number of Openings: 10-30 layers

Max Pressure: 200-300 tons

Platen Size: 1220×2440mm to 1830×3660mm

Temperature Range: 120-200℃

Control Accuracy: Temperature ±1℃, Pressure ±1%

Heating Methods: Steam, Thermal Oil, Electric

Automation Level: Fully automatic with PLC control

Key Advantages

1. High-Quality Output: Uniform temperature and pressure distribution ensure consistent density and structural stability of plywood;

2. High Efficiency: Multi-opening design allows simultaneous pressing of multiple panels, while automation reduces manual intervention;

3. Energy Efficiency: Closed-loop heating and insulation design minimize energy consumption, complying with green production standards;

4. Intelligent Control: Integrated PLC and touchscreen interface enable real-time monitoring of temperature, pressure, and production data, supporting fault diagnosis and remote maintenance.

Request Your Plywood Solution Now! 3D plant layout, on-site commissioning & global spare parts – Dominate the premium board market today!

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com